8 Best Manufacturing ERP Systems in Malaysia 2023-2024

Malaysian manufacturers grapple with complex supply chains, production efficiency, and competitiveness. Traditional management methods are often time-consuming, and error-prone, and lead to increased costs and customer dissatisfaction.

As Malaysian businesses expand, the need for efficient, comprehensive solutions intensifies. Lack of a reliable manufacturing ERP results in bottlenecks, miscommunication, and decreased performance, impacting profitability and long-term success.

The best manufacturing ERP systems in Malaysia provide a tailored, integrated solution. Implementing an ERP for manufacturing allows companies to manage supply chains effectively, optimize production, and make informed decisions for a competitive edge, unlocking new opportunities for a prosperous future.

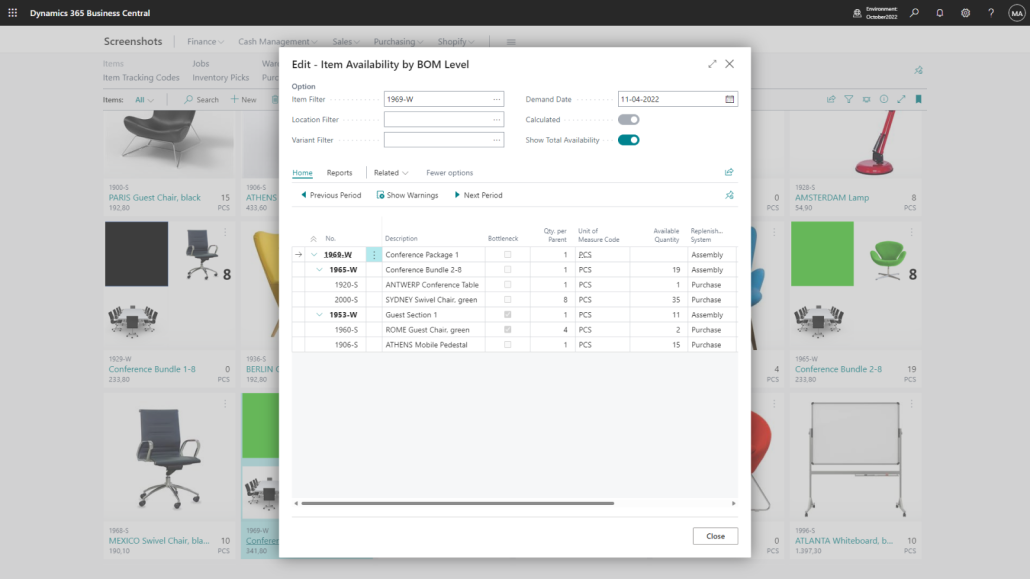

1. Dynamics 365 Business Central

Dynamics 365 Business Central is a versatile ERP business management solution for small and mid-sized organizations that streamlines processes in finance, manufacturing, sales, shipping, project management, and services. With easy customization, it supports specialized industries and regional operations. It’s quick to implement, simple to configure, and designed with a focus on usability and innovation.

Dynamics 365 Business Central is an ERP financial business management solution meaning that you must implement the Business Central Financial Management first and on top of that you can implement the Manufacturing module and/or others. Overall it’s one of the best ERP systems in Malaysia.

This makes it less suitable for companies that are seeking only MRP solution or solution that only provides for manufacturing production.

Advantages:

- Best for Small-Medium Size manufacturing. (50-500 employees).

- Best for diverse companies with different operations (manufacturing, distribution, etc.) because of the wide range of capabilities.

- Very flexible and customizable which allows the system to meet unique business needs.

- Seamless integration with Microsoft products such as Microsoft 365, Power Platform, and Azure.

- Easy to integrate with third-party software to centralize operations.

- Highly scalable allowing companies easily move to the more complex Microsoft ERP solutions developed for large organizations.

- Multi-deployment options include cloud, on-premises, or hybrid.

- Seamless integration with local Malaysian requirements, such as tax regulations, currencies, and languages.

Additional resources:

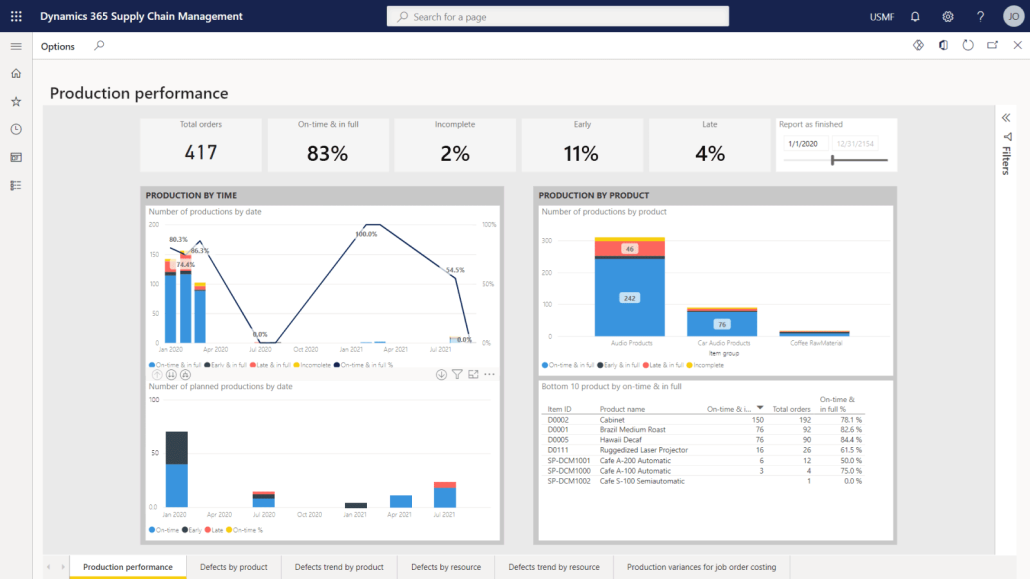

2. Dynamics 365 Supply Chain Management

Dynamics 365 Supply Chain Management is a comprehensive ERP solution for organizations seeking to optimize their supply chain operations. It streamlines procurement, inventory, manufacturing, and distribution processes while improving visibility and collaboration.

With advanced features like IoT and AI, it enhances forecasting, resource planning, and product quality. Seamlessly integrated with the Microsoft ecosystem, it supports customization and ensures adaptability to unique business needs.

Unlike Dynamics 365 Business Central, Dynamics 365 Supply Chain Management does not require you to have any financial management module. Its wide range of capabilities makes it one of the best Manufacturing ERPs in Malaysia.

Advantages:

- Best for medium to large manufacturing organizations (250+).

- Seamless integration with Microsoft products such as Microsoft 365, Power Platform, and Azure.

- Easy to integrate with third-party software to centralize operations.

- Wide range of functionalities across manufacturing, warehouse, supply chain, service, and sales management.

- Multi-deployment options include cloud, on-premises, or hybrid.

- Advanced AI and IoT technologies can be integrated to improve predictive maintenance, enhance demand forecasting, and optimize resource planning.

- Enhanced collaboration among departments, suppliers, and customers for a more responsive supply chain.

- Real-time visibility into supply chain operations for better decision-making and resource allocation.

- Streamlined processes that increase efficiency and reduce costs in procurement, production, and distribution.

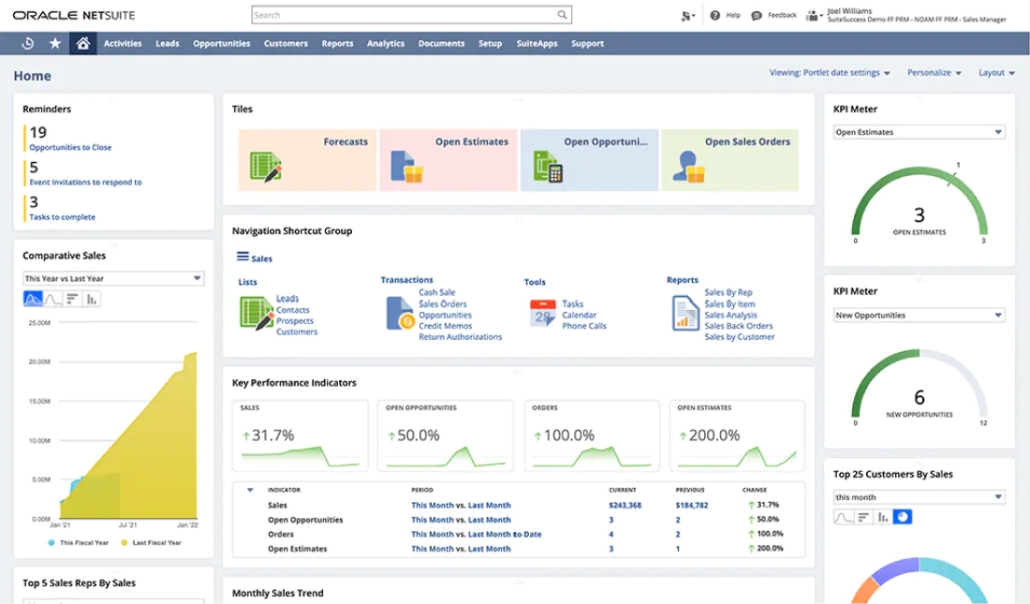

3. Oracle NetSuite

Oracle NetSuite is a comprehensive, cloud-based Enterprise Resource Planning (ERP) solution that helps manufacturing companies to standard operation and moves from basic accounting or manufacturing software. It streamlines key processes such as financials, operations, and customer relations management.

Also, check out the best Oracle NetSuite alternatives in Malaysia.

Advantages:

- Best for SMBs (30-200 employees) that are looking for standardization and require less customization or flexibility.

- Relatively easy and quick to implement compared to other ERP systems.

- Native cloud-based infrastructure for easy implementation, remote accessibility, and lower total cost of ownership.

- Real-time analytics and reporting for data-driven decision-making and process improvement.

- Great to standardize your business processes.

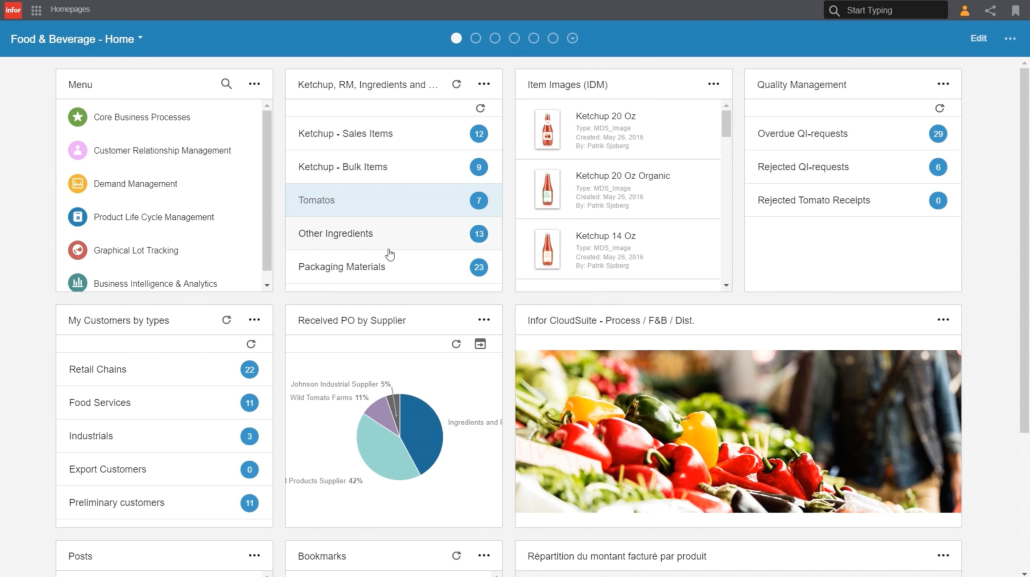

4. Infor M3

Infor M3 is a comprehensive Enterprise Resource Planning (ERP) software solution designed for medium to large-sized businesses, particularly those in the manufacturing, distribution, and service industries.

Infor M3 offers a wide range of features and functionality to help organizations manage their core business processes, such as finance and accounting, supply chain management, and manufacturing.

Advantages:

- Best for medium size manufacturing and distribution companies especially in retail apparel or F&B. (100-300 employees)

- Focused on manufacturing and distribution industries.

- The software is a flexible ERP solution with a broad and diverse set of capabilities.

- Great to customize for complex or unique orders.

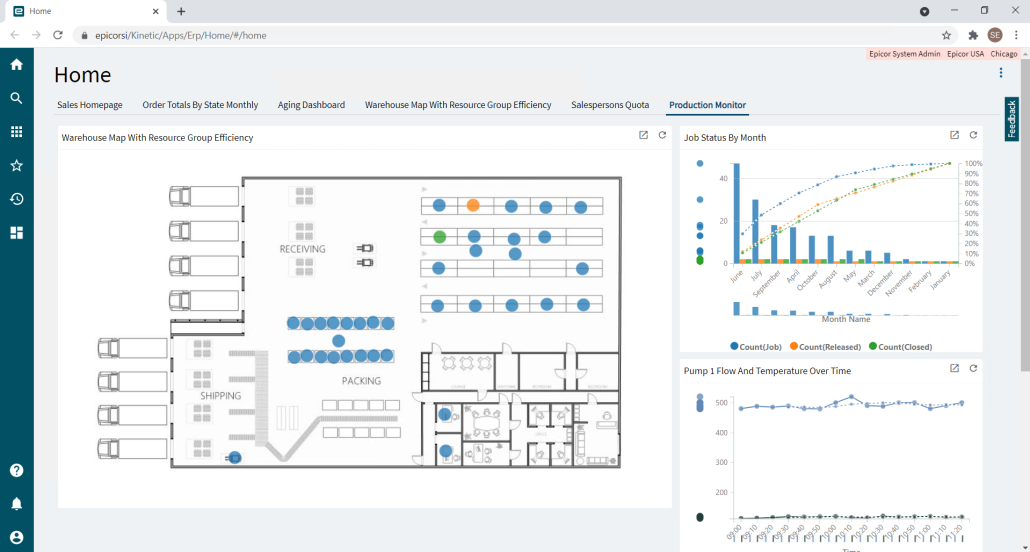

5. Epicor Kinetic

Epicor Kinetic is an ERP solution designed to support the unique needs of small to mid-sized businesses in the manufacturing industry. Epicor Kinetic leverages the power of the cloud to provide a scalable, secure, and cost-effective ERP solution that is accessible from any location.

Advantages:

- Best for small and medium size companies (50-250 employees).

- Highly focused on manufacturing, distribution, and retail industry.

- Multi-deployment options include on-premises, cloud, or hybrid options.

- Build on low-code technology that allows certain adjustments or customization to be easily made without changing the code.

- Relatively high ROI, low risk, and fast-to-implement ERP solution thanks to its focus on certain industries.

- Great product configuration capabilities for manufacturing that needs to configure their own products.

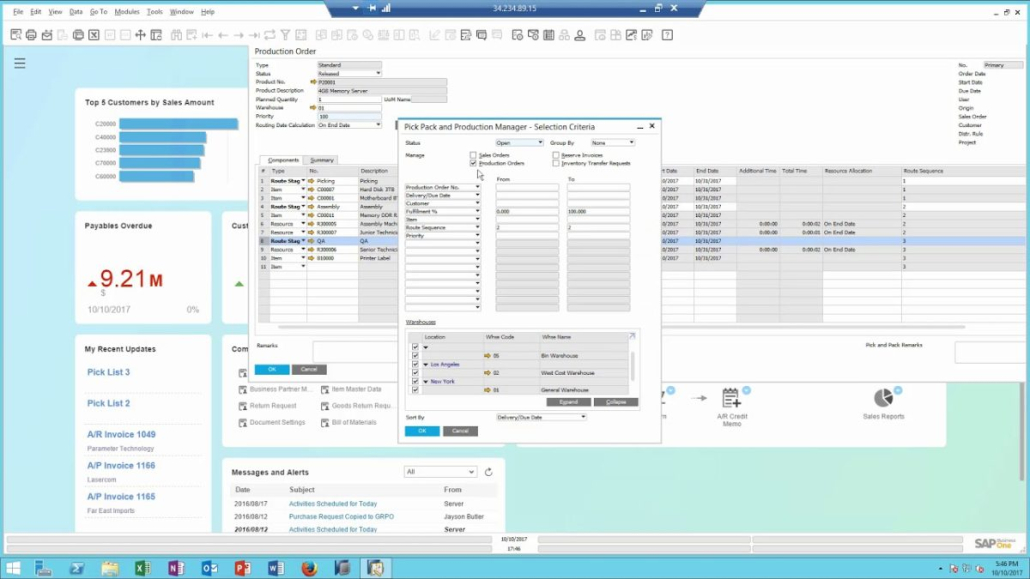

6. SAP Business One

SAP Business One is an all-in-one solution tailored to meet the needs of small and medium-sized enterprises, it offers automation of vital business functions such as financials, operations, and human resources.

It covers everything from accounting and financials to purchasing, inventory, sales, and customer relationship management to reporting and analytics.

However, because of SAP B1 requirements to implement a minimum of 10 modules, this system is not best for businesses that are looking for only manufacturing modules or to implement only a few related modules such as financial, supply chain, and manufacturing management modules.

Also, check out the best SAP Business One alternatives in Malaysia and Business Central vs SAP Business One.

Advantages:

- Best for small-medium-size manufacturing companies. (50-300 employees)

- All-in-one solution that allows you to centralize your operation with one centralized solution and replace all your legacy systems.

- Very mature product with many broad capabilities.

- It is relatively quick to be implemented and deployed for business.

- Great reporting capabilities.

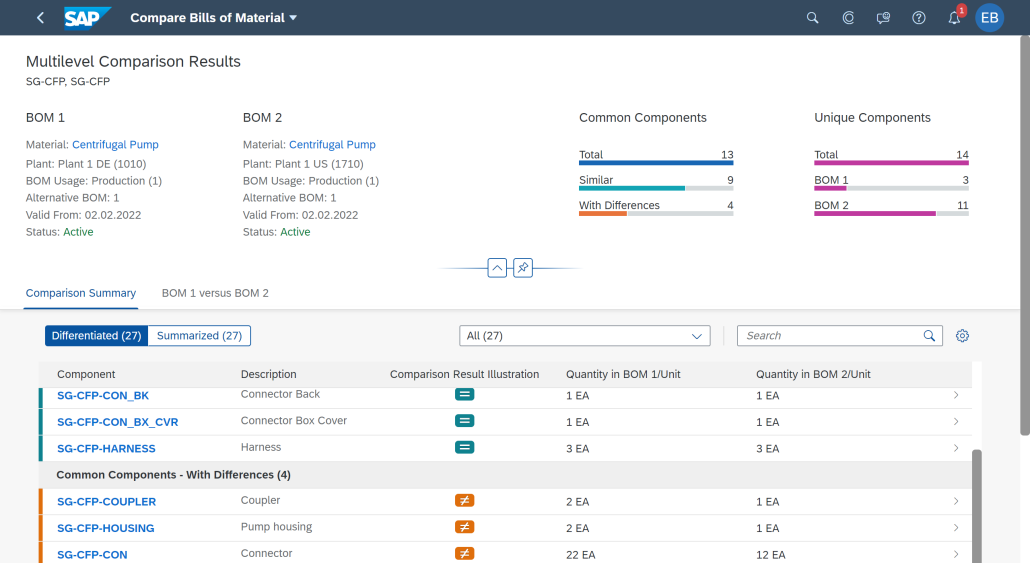

7. SAP S/4HANA

SAP S/4HANA is an advanced, next-generation ERP software suite developed by SAP SE. It is built on the company’s in-memory database platform, SAP HANA, which enables real-time data processing and analytics. S/4HANA is designed to help businesses manage their operations more efficiently, make faster and more informed decisions, and simplify their IT landscapes.

SAP S/4HANA offers a wide range of functionalities across various business domains, including finance, human resources, sales, supply chain management, procurement, and manufacturing.

Advantages:

- Best for large global manufacturing organizations (1,000+ employees)

- They provide a lot of broad capabilities to empower even more complex and unique manufacturing companies.

- A highly customizable solution that enables companies to tailor the solution to their exact needs.

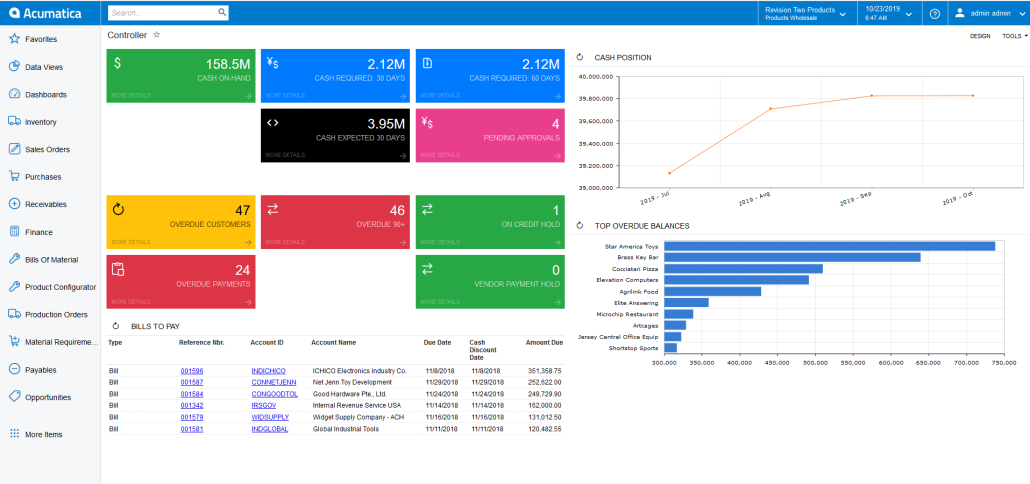

8. Acumatica

Acumatica is a highly regarded cloud-based ERP software that offers a complete suite of financial and business management tools for small and mid-sized businesses. With a range of modules including accounting, customer management, distribution, and project management, all easily accessible through a single platform, Acumatica is designed to help companies streamline their operations, make informed decisions, and improve efficiency.

Advantages:

- Best for small and medium-sized manufacturing companies. (25-200 employees)

- Great manufacturing capabilities with a focus on this industry.

- Provides flexibility and is relatively easy to configure the software without hiring IT professionals.

- It’s easy-to-use ERP software for manufacturing that is easy to understand and use.

- Very affordable ERP system for companies in Malaysia.

- The pricing is based on how many transactions your company does in a day with unlimited users.

Final Advice

Above are some of the most commonly used Manufacturing ERP systems by Malaysia companies such as Dynamic 365 Business Central, Dynamics 365 Supply Chain Management, and Epicor Kinetic.

However, which ERP system is best is very subjective to a company’s needs, budget, and requirements. Therefore, it’s essential to the way the pros and cons of each individual ERP system and contacts local partners to help you better understand how their software can fit within your organization.

To learn more about Dynamics 365 for Manufacturing, please contact us and our experts will provide you with relevant information and if required prepare a personalized demonstration of a recommended Dynamics 365 application.

FAQs to Manufacturing ERP in Malaysia

Here we are going to answer some of the most common questions when it comes to Manufacturing ERP.

What is Manufacturing ERP?

Manufacturing ERP (Enterprise Resource Planning) is a comprehensive software solution that integrates various business processes within a manufacturing organization. It streamlines operations, improves efficiency, and enables real-time data sharing across departments, such as production, inventory, sales, and finance, for better decision-making and resource management.

Why is ERP Software Used in Manufacturing?

ERP software is used in manufacturing to enhance operational efficiency, optimize resource management, and facilitate data-driven decision-making. Integrating key processes like production, inventory, sales, and finance, enables real-time information sharing, improves collaboration, and streamlines workflows. Consequently, manufacturers can reduce costs, increase productivity, and respond more effectively to market demands.

Which ERP software is used in the manufacturing industry?

There are numerous ERP software options for the manufacturing industry, with some popular choices being:

· Microsoft Dynamics 365

· SAP S/4HANA

· Oracle NetSuite

· Infor CloudSuite Industrial

· Epicor ERP

Each solution offers unique features and capabilities. The best choice depends on a manufacturer’s specific needs, business size, and industry requirements.

What are MRP and ERP in manufacturing?

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) are software systems used in manufacturing to optimize processes and resource management. MRP focuses on production planning, scheduling, and inventory control, helping manufacturers efficiently manage raw materials, components, and finished goods. ERP, a more comprehensive solution, integrates various business functions, including production, inventory, sales, and finance, streamlining operations and enabling data-driven decision-making.

Does ERP include manufacturing?

Yes, ERP (Enterprise Resource Planning) systems often include manufacturing modules as a core component. These modules help manage production processes, scheduling, inventory control, and quality assurance, enabling manufacturers to optimize their operations, streamline workflows, and enhance overall efficiency. By integrating manufacturing with other business functions, ERP systems facilitate real-time data sharing and improved decision-making.