Due to the increased popularity of outsourcing shipping and logistics requirements, a growing number of businesses are using shipping providers or third-party logistics providers. An ERP inventory management system enables you to integrate with external partners, ensuring all systems communicate with each other. Stock, order, and shipping information is therefore synced across the entire supply chain.

Supply chain management is an essential component of enterprise resource planning solutions that many companies have adopted. Companies need to interact with various suppliers and partners to obtain the raw materials, products, and resources at the right time and at the right amount.

Businesses are increasingly focusing on several supply chain strategies to boost operation productivity, enhance product quality, and cut down on business costs.

As operations become more extensive and globalized, the integration of SCM becomes all the more important. ERP solutions can support multiple modes such as make-to-order, engineer-to-order, and configure-to-order and provide operations support across multiple sites in real time. As a result, businesses can avoid supply chain disruption.

Important Functions in ERP Inventory Management System to Look For

ERP System is designed to centralize business operations and data and streamline processes to simplify, standardize and speed up things.

This helps inventory-based businesses to improve their inventory management, better manage growth and complexity associated with it and improve business planning.

To achieve that ERP inventory management system should provide a certain set of functions or features in order to deliver the benefits. Here are the most important ERP inventory management features:

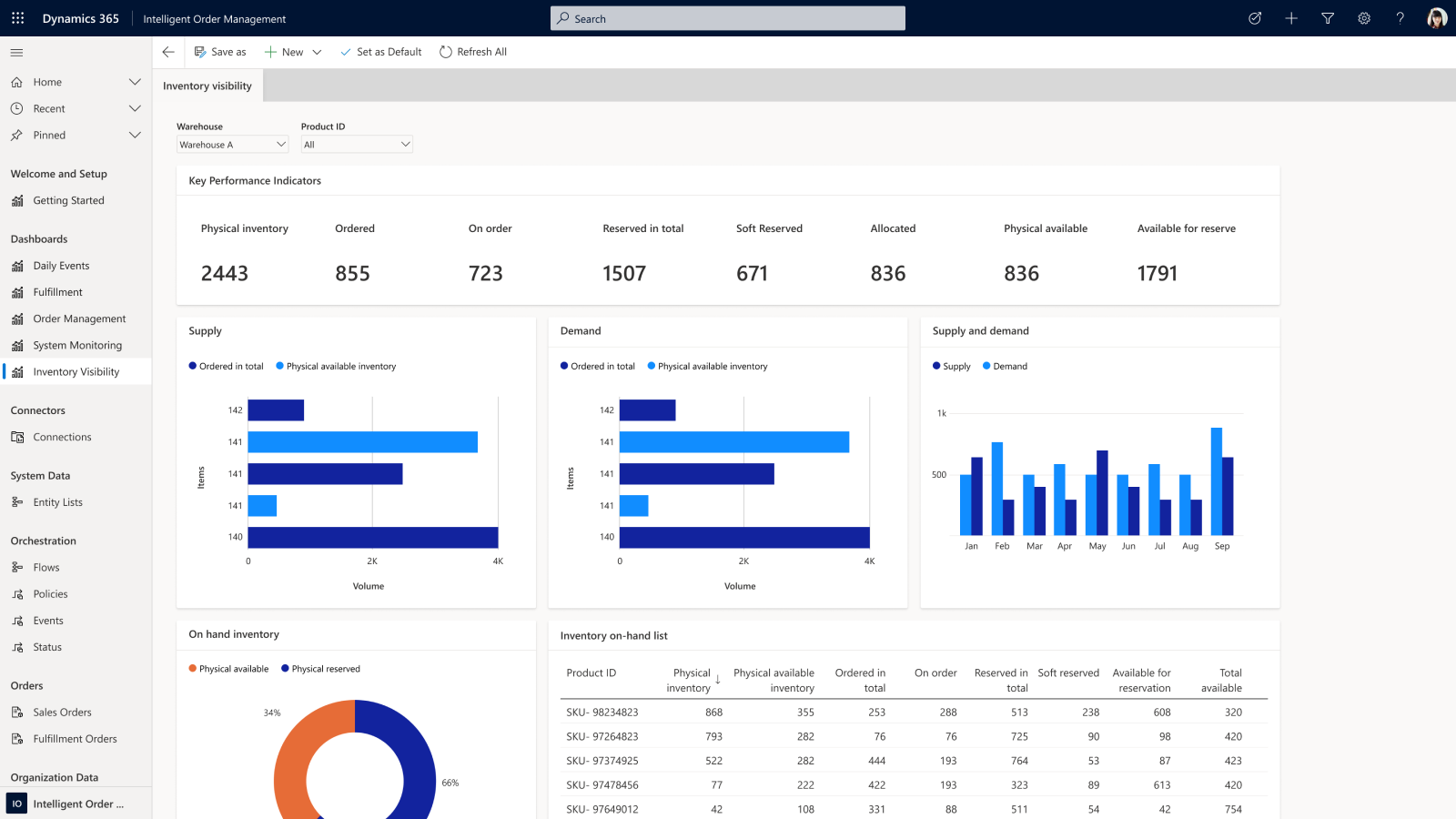

Inventory Management

Inventory management should help you to perform the following tasks:

- Inbound operations

- Quality assurance

- Inventory activities

- Outbound operations

- Inventory control

Warehouse Management

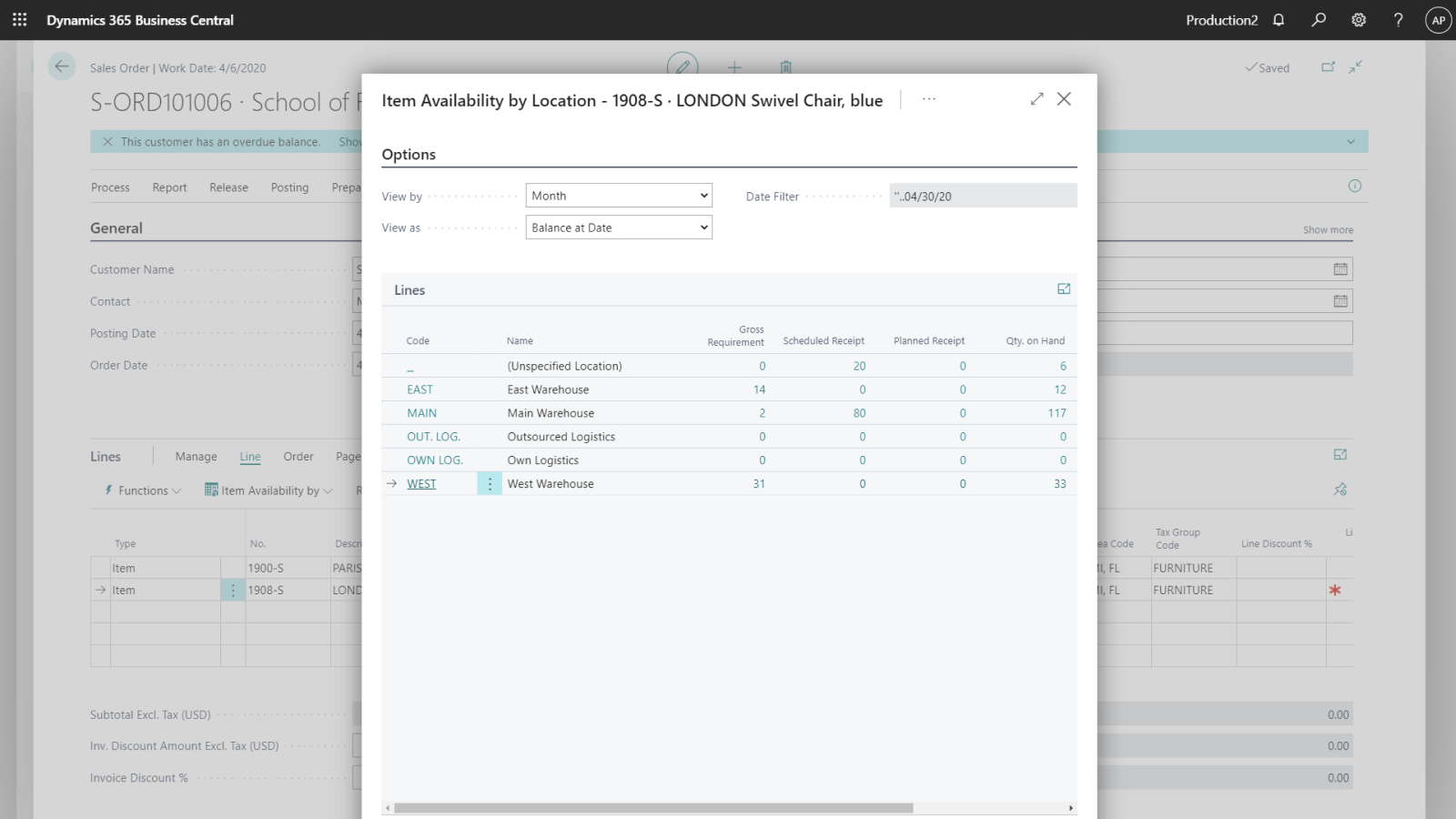

Warehouse management lets you manage warehouse processes in manufacturing, distribution, and retail companies. This module has a wide range of features to support the warehouse facility at an optimal level, at any time. Warehouse management is fully integrated with other business processes such as transportation, manufacturing, quality control, purchase, transfer, sales, and returns.

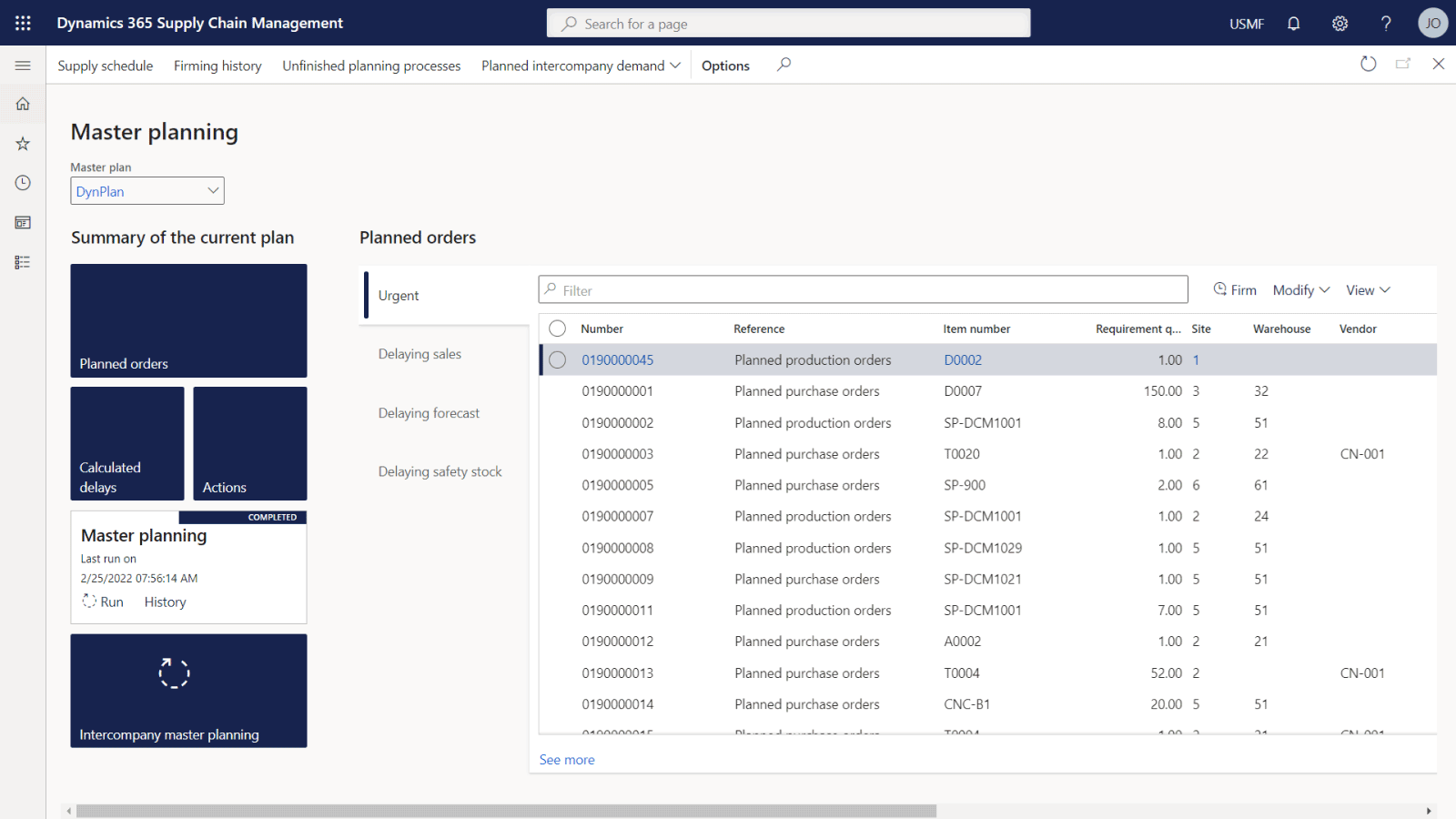

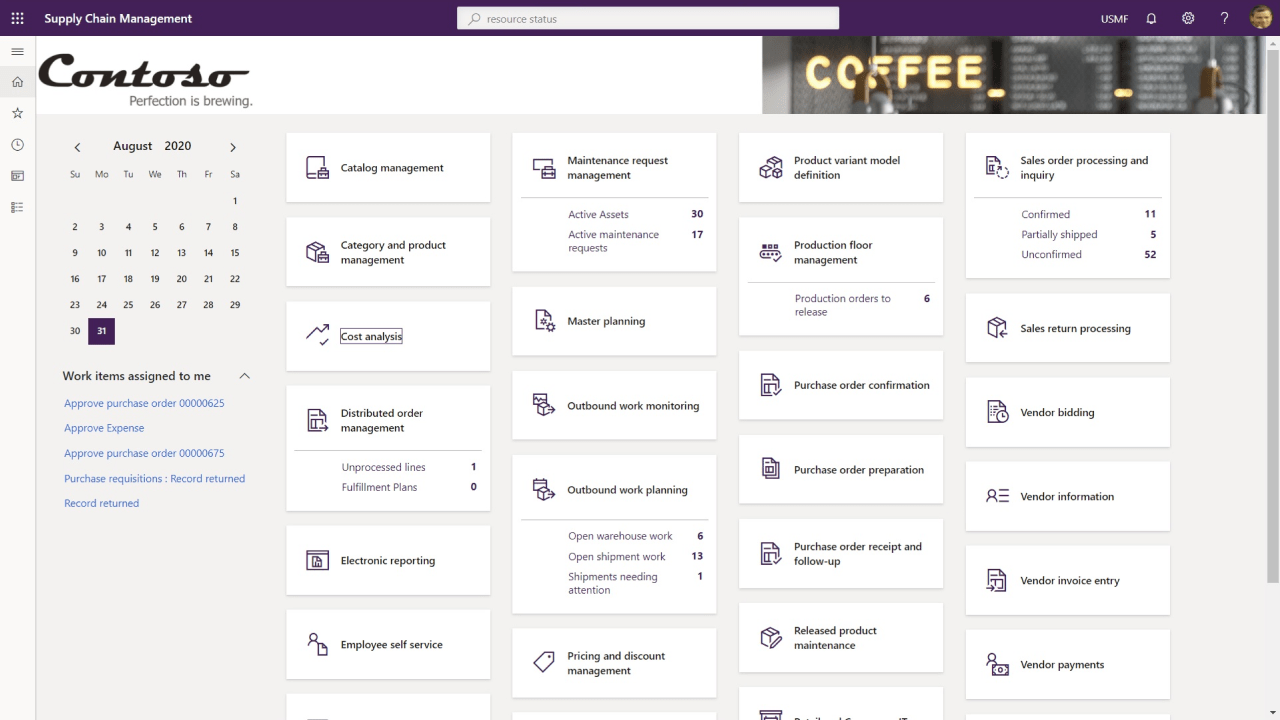

Supply Chain Management

Supply Chain Management lets you manage your stock based on actuals, demand, and availability using built-in intelligence, sales forecasts, and expected stock-outs to automatically create purchase orders.

Companies can return to normal and ramp up faster due to the agility in planning, sourcing, and distribution processes driven by non-monolithic business solutions and de-risk from future disruptions. With a resilient supply chain, organizations are better equipped to generate positive cash flow by optimizing resources, staying profitable, retaining market share, and remaining competitive.

Manufacturing Management

When demand is planned for and the materials have been issued according to production BOMs, then the actual production operations can start and be executed in the sequence defined by the production order routing.

An important part of executing production, from a system point of view, is to post-production output to the database to report progress and to update inventory with the finished items. Output posting can be done manually, by filling and posting journal lines after production operations.

Or, it can be done automatically with the use of backward flushing. In that case, the material consumption is automatically posted along with output when the production order changes to finished.

As an alternative to the batch journal for output posting for multiple product orders, you can use the Production Journal page to post consumption and/or output for one production order line.

Before you can begin to produce items, you must make various setups, such as work centers, routings, and production BOMs.

Procurement & Sourcing Management

Procurement and sourcing cover all the steps from identifying a need for product and services through procuring the product, receipt, invoicing, and processing of payment with vendors. Procurement processes can be configured toward specific business needs by defining purchasing policies and workflows.

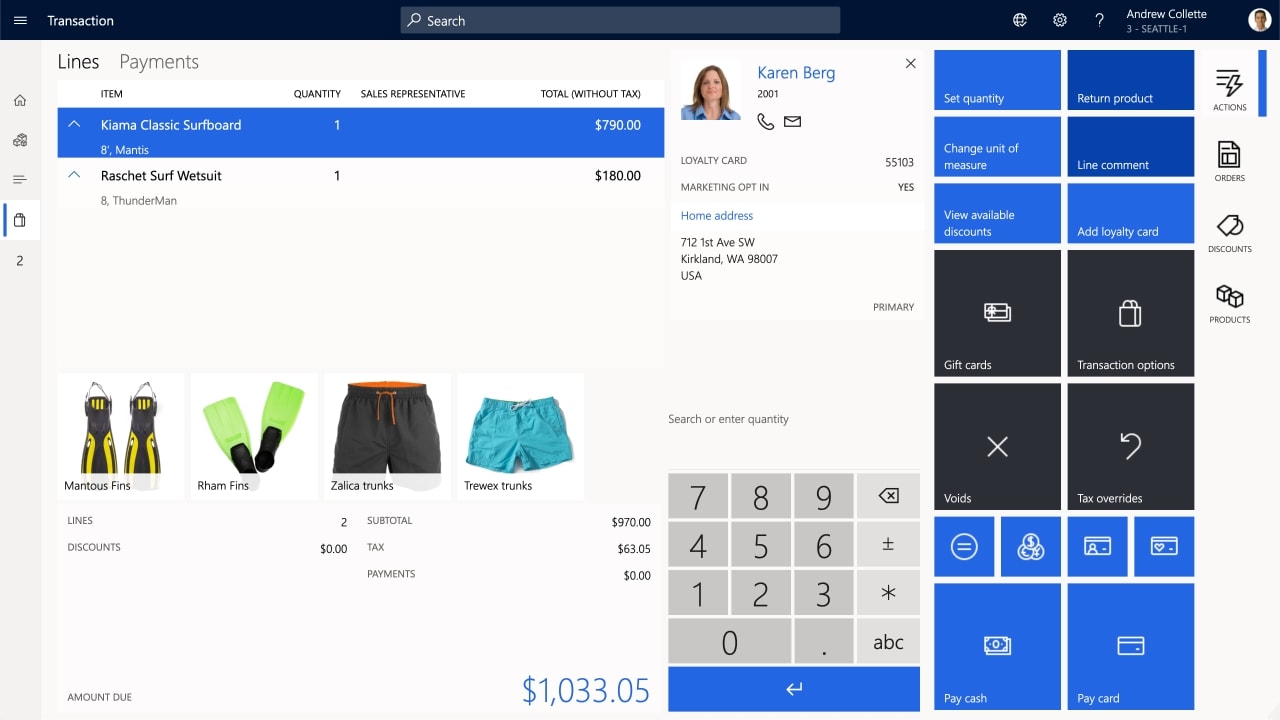

Sales & Marketing Management (CRM)

You can use sales and marketing to obtain, store, and use various types of data in the sales flow. This data includes the original sales initiative, future follow-up action, and additional sales.

Asset Management

Asset Management enables you to efficiently manage and carry out tasks related to managing and servicing many types of equipment in your company, for example, machines, production equipment, and vehicles.

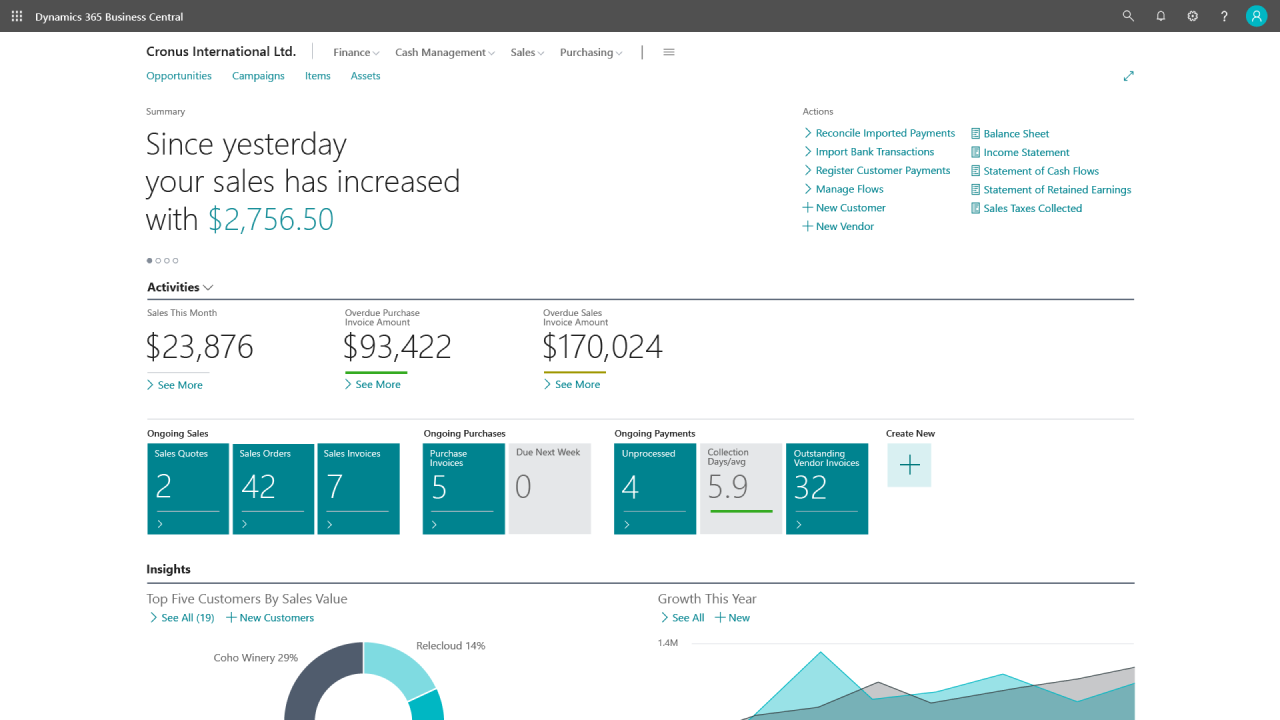

Accounting and Finance Management

ERP Inventory management should provide at least a default configuration that includes a chart of accounts and standard posting groups that make the process of assigning default general ledger posting accounts to customers, vendors, and items more efficient.

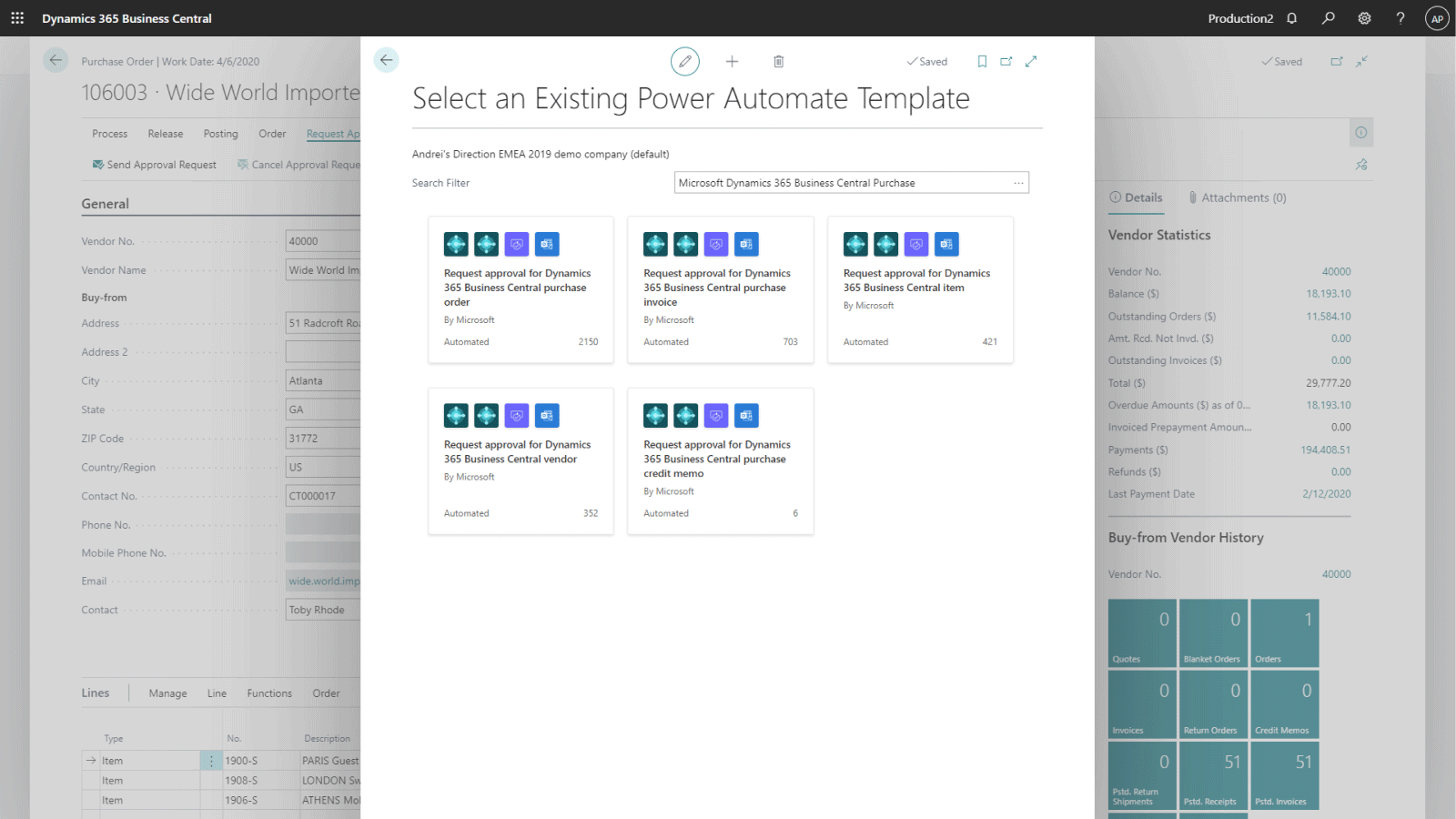

Automation

Inventory automation helps you improve productivity and get more done with easy-to-create workflows and audit trails.

By using automation you can connect workflows across sales, inventory, purchasing, supply chain, and accounting to automatically track cash flow and secure purchasing, credit authorization, vendor payment processes, and more.

Analytics and Reporting

Centralized operations enable you to access your data across accounting, sales, purchasing, inventory, and customer interactions for an up-to-date, end-to-end view of your business.

Reporting and analytics involve many business areas across the company and it is important to ensure that all relevant employees have access to the data they need.

For example, finance and accounting officers need accounting data from the general ledger; a warehouse manager, on the other hand, will need to use inventory-related data, while the head of the company will need specific information from data regarding the company’s efforts and performance goals, also called KPIs, which provide information on the direction and speed of meeting the company’s strategic objectives.

How to Get Started with ERP Inventory Management System

At first, it’s important to realize if you really need an ERP inventory management system in the first place or if a standard inventory management system is sufficient for your needs as ERP inventory management is more expensive and the price of it can go from RM100,000 and beyond depending on the size of your team, customization, and other requirements.

Therefore, investing in a more robust ERP inventory management system should be seen as a long-term investment with the goal of better managing the growing business.

With that being said, to get started with the right ERP inventory management you’ll first need to decide exactly what you are looking for.

As mentioned at the beginning, there are basically two versions of the ERP inventory management system and on top of that, each ERP vendor provides different functions and capabilities.

Therefore, it’s recommended to make a list of ERP vendors or their partners and contact them directly to explain your needs and requirements. Most of them should provide you with a free consultation on their software and if required also a free personalized demonstration of the suitable system.

Remember, the investment can reach 100ks RM therefore you should be very thorough when selecting the right ERP system.

Here we have created a few guides to help you with that:

Also keep reading to learn more about Microsoft Dynamics 365 as your ERP inventory management system.

Dynamics 365 as Your ERP Inventory Management System

Microsoft Dynamics 365 is a suite of ERP & CRM business applications tailored to meet your business needs and grow without.

Microsoft offers multiple ERP system options with inventory management, each offering different features and capabilities that are suitable for different businesses.

Therefore, here are the four Microsoft ERP applications with inventory management:

Dynamics 365 Business Central