6. Days Inventory Outstanding (DIO)

Days inventory outstanding (DIO) is the average number of days that a company holds its inventory before selling it. The day’s inventory outstanding calculation shows how quickly a company can turn inventory into cash. It is a liquidity metric and also an indicator of a company’s operational and financial efficiency.

Days inventory outstanding is one component of the cash conversion cycle (CCC), together with days payable outstanding (DPO) and days sales outstanding (DSO). The CCC measures how quickly a company converts its investment in inventory into cash

7. Stockout Rate

The Stockout rate is the percentage of items not available when needed for sale. It is calculated as items, not in stock divided by the total available items in inventory. The average stockout rate is about 8%, and it rises when products are on sale. A high stockout rate can lead to significant lost sales.

8. Back Order Rate

The Back Order Rate KPI measures how many orders cannot be filled at the time a customer places them. A high back order rate means your customers are forced to wait while you attempt to fill their order, which will adversely affect customer satisfaction and retention in the long term.

This supply chain KPI is closely related to the inventory accuracy KPI and percentage of out-of-stock items KPI. Monitor this KPI to identify why certain items are not in stock and to deal with trends (such as seasonal demand) that may affect your performance.

How Do You Analyze Inventory?

In order to properly conduct inventory analysis, it’s important to implement inventory analysis methods mentioned above as well as to track important inventory KPIs. Besides that, it’s also important to implement relevant inventory management techniques and best practices in order to effectively optimize your inventory based on your inventory analysis.

How Does Inventory Management System Help with Inventory Analysis?

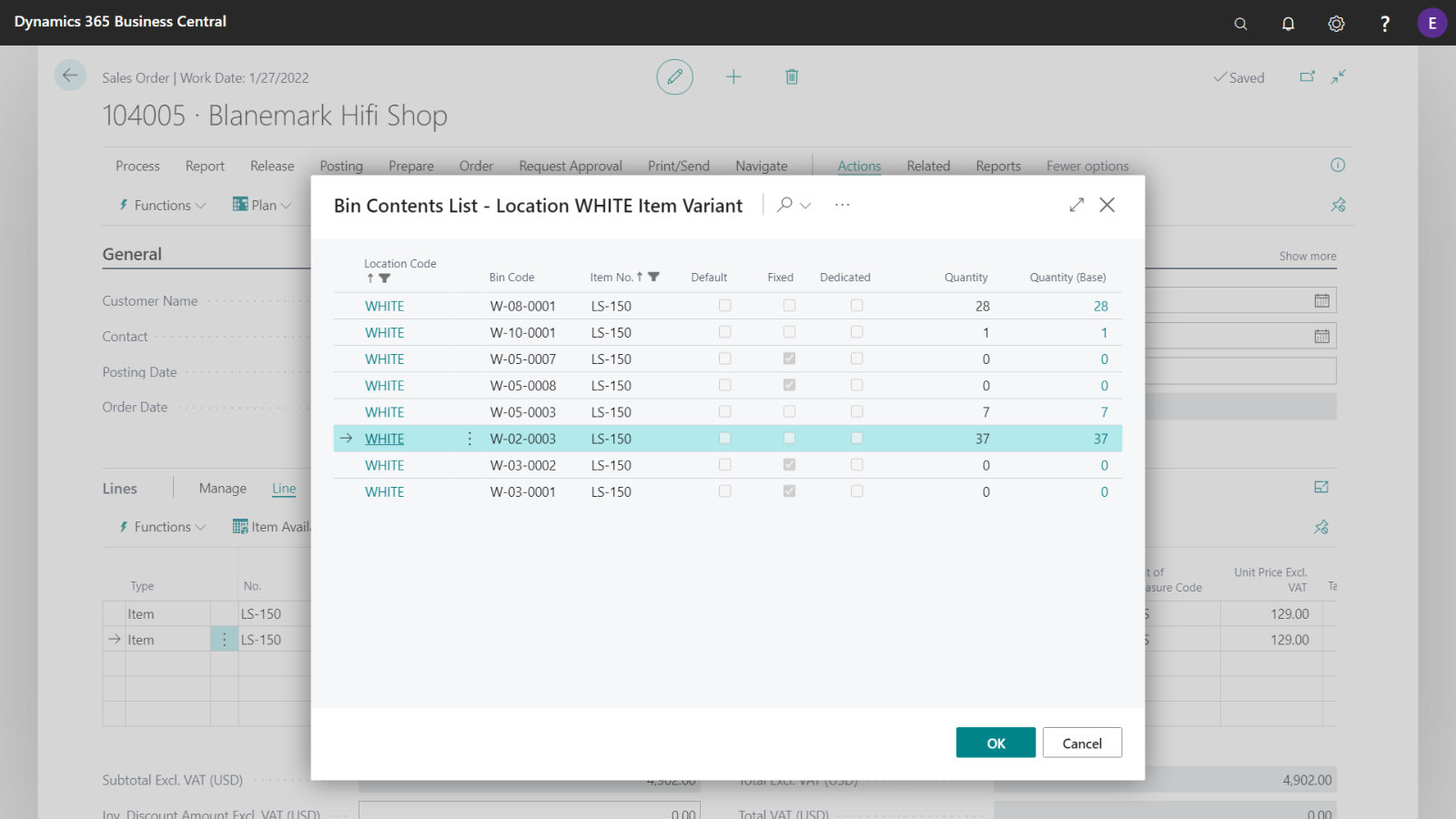

An inventory management system helps you collect data from multiple sources, whether from your barcode scanner, eCommerce, warehouse, or manually from your employees. It provides real-time inventory analysis based on collected data and historical data in order to improve your inventory forecasting and purchasing.

An inventory management system optimizes inventory levels and ensures product availability across multiple channels. It provides a single, real-time view of items, inventory, and orders across all locations and selling channels.

It keeps track of changes to inventory at all three stages and adjusts asset values and costs accordingly and improves your overall inventory process efficiencies in order fulfillment, purchasing, handling, stock levels, customer request, and more.

Dynamics 365 Business Central with Shopify Integration

The Shopify connector gives customers the ability to connect their Shopify store (or stores) with Business Central in order to maximize business productivity. By using the Shopify connector, they can manage and view insights from their business and their Shopify online store as one unit.

Microsoft Dynamics 365 Business Central is teaming up with Shopify to help our customers create a better shopping experience. While Shopify provides merchants with an easy-to-use e-commerce solution, Dynamics 365 Business Central offers comprehensive business management across finance, sales, service, and operations teams within a single application. Seamless connection between the two systems will synchronize orders, stock, and customer information to ensure merchants can fulfill orders faster and better serve customers.

This can result in:

- Agile processes: Connecting Dynamics 365 Business Central with Shopify will help merchants all over the world implement more agile online business processes while keeping people focused on selling.

- Rapid response: With connected data from across online stores and business operations, merchants can rapidly respond to consumer demands to adjust product pricing and merchandising.

- Multiple scenarios: With support for multi-tier pricing structures and multiple currencies, companies, and entities, Dynamics 365 Business Central will support multiple Shopify store scenarios with ease.

- Improved visibility: By connecting Shopify and Dynamics 365 Business Central, merchants will improve visibility into stock, pricing, existing customers and order history, order status, billing,

and payments. Better visibility means faster customer inquiry responses, timely returns and refunds, and more accurate order processing.

Try Dynamics 365 Business Central as Your ERP Inventory Management System