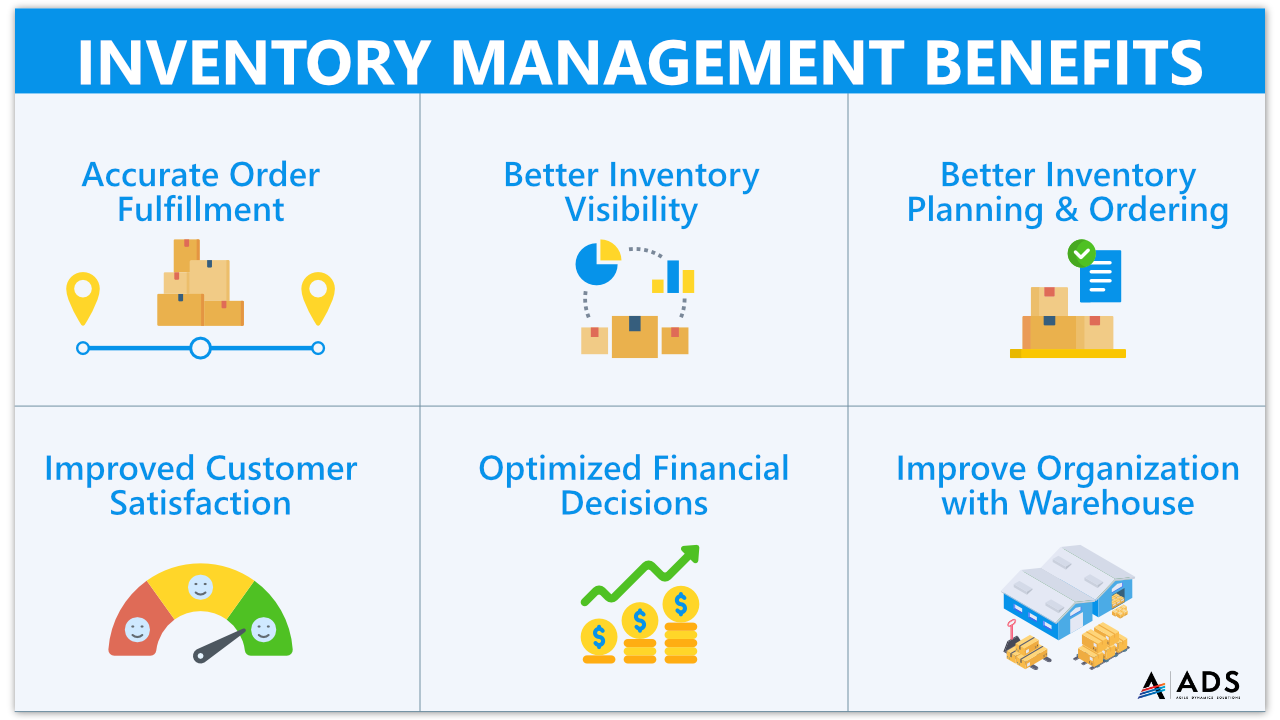

Inventory management brings some excellent benefits to your company, and you can improve many different aspects of your organization. Here is a list of the main inventory management benefits:

- Accurate Order Fulfillment: Improve your inventory visibility and ensure that your customers get the right item or avoid getting orders of inventory that are out of stock from your website or by your salespeople. Reduce inaccuracies in filling orders, high return volumes, and a loss of customer base.

- Better Inventory Visibility: Get a better view of where is your inventory, whether it is stored in multiple locations, on the way from a supplier, or to your customer, you will have a better view of your inventory.

- Better Inventory Planning and Ordering: Reduce the complexity of accurately forecasting which products are and will be needed. With inventory management, you’ll have a better view of your inventory to avoid overstocking or stockouts and have the right amount of inventory for your best-selling and low-selling inventory.

- Improved Customer Satisfaction: Inventory management helps you to deliver the right items at the right time to your customers, improve quality control, avoid delays in orders, or do refunds because your inventory is not available. All this will lead to happy customers and receiving more orders from them.

- Optimized Financial Decisions: One of the biggest inventory management benefits is it allows you to make better financial decisions whether it is better inventory planning and ordering, allowing your employees to be more productive and reducing overtime, to focus on the right inventory to market and sell to improve profitability and reduce the risk of inventory becoming obsolete.

- Improve Organization Within Warehouse: Proper inventory management leads to better order fulfillment, improve quality control checks, storing management, inventory movement, employee movement, employee efficiency, and reduces employee risks. Inventory management is the first thing you should do to improve your warehouse operations.

5 Objectives of Inventory Management

1. Having Material Available

One of the main objectives of inventory management is to ensure you are always having material available whenever the production department needs them ensuring that production is not stopped or slowed down due to a lack of resources.

That’s why it is important to keep a buffer stock of all important materials in order to keep production on track.

2. Improve Order Fulfillment

Improved order fulfillment is another important objective of inventory management to ensure you avoid situations when you don’t have stock to fulfill all your orders and you’ll have to keep your customer waiting or provide them with a refund.

Situations such as sales making a sale just to later find out your company won’t have enough inventory to complete the order, or a customer bought your product from your eCommerce store that is actually out of stock are one of the many order fulfillment problems that can cost you customers, money, and business reputation.

To not experience this, an inventory management system should be used, and team members should be knowing the inventory situation.

3. Having the Right Amount of Stock

Another major objective of inventory management is to ensure you are having the right amount of stock to ensure stockouts or overstocking does not happen.

For manufacturing, you always need to ensure supplies should be easily available for all stages of production, from raw materials to completed goods. You need to make sure you have enough of the necessary material on hand to meet client demand without having to cut corners and being concerned about running out of materials, and components and stopping production.

For retail, this helps you to track the best-selling and low-selling items, so you don’t end up with too much stock with items that are hard to sell and too little stock for those items that are selling by themselves.

Inventory management helps companies that handle inventory to optimize their inventory stock levels so they don’t spend too much capital on inventory, but also are not out of stock which could mean losing customers to competitors.

4. Keeping Wastage and Losses to a Minimum

The fourth objective of inventory management is to keep wastage and losses to a minimum. When businesses don’t have a complete view of their inventory it is easy for a stock to be misplaced, stolen, disappeared, or become obsolete because the business did not sell it on time.

Inventory management helps you to ensure that these occurrences are being limited or completely reduced by giving you a full view of your inventory, where it is stored, and its movement of it.

Having processes and documents in place helps avoid waste and protects your business from theft or losses. This is especially important when you are handling large quantities of goods.

Inventory management attempts to minimize inventory waste at all stages, such as during storage in godowns or during production in the plant.

Normal or uncontrolled waste should not be allowed to exceed a permissible level, whereas abnormal and unmanageable wastage should be carefully regulated.

5. Increase Profit

And the last main objective of inventory management I would like to mention here is to help you increase profit.

An inventory management system can help you analyze your historical data and product sales patterns and make a suggestion for you to have enough stock to avoid being out of stock and losing profit.

It can also help you identify any low-selling items for you to market in order to sell them before they become obsolete and liability to your company.

Inventory management gives you essential insights on your sales to keep profit high and cost low, keeping your goods going in and out and helping you identify any important trends that you should react to.

Inventory Management Techniques

The more inventory you handle, the more SKUs you have in your warehouse, and the more complex your operation becomes. Therefore, over the years, businesses have developed different techniques to improve handling and managing inventory.

And while every business is different and unique, inventory management techniques are universal and can be used across different industries and businesses I am sure some of these will be applicable to your business as well or you already might be using some of these in your business.

With that here is a list of major inventory management techniques:

- ABC Analysis: ABC analysis is an inventory management technique that determines the value of inventory items based on their importance to the business. ABC ranks items on-demand, cost, and risk data, and inventory managers group items into classes based on those criteria.

- Demand Forecasting: Demand forecasting is the process of making estimations about future customer demand over a defined period, using historical data and other information.

- Bulk Shipments: Bulk shipping is the transportation of goods in large quantities, usually not packed but loaded directly into a vessel. Such goods are grains, petroleum products, iron ore, and more. These types of goods are referred to as bulk cargo. These are unpacked goods loaded on board a vessel.

- Economic Order Quantity: Economic order quantity is an inventory management technique that helps make efficient inventory management decisions. It refers to the optimal amount of inventory a company should purchase to meet its demand while minimizing its holding and storage costs.

- Minimum Order Quantity: Minimum order quantity is the fewest number of units a business is willing to sell to a single customer at once. While a retail store may be happy to sell a single t-shirt or one head of lettuce, it isn’t usually profitable to sell a single unit.

- Just In Time: The just-in-time (JIT) inventory system is a management strategy that aligns raw-material orders from suppliers directly with production schedules. Companies employ this inventory strategy to increase efficiency and decrease waste by receiving goods only as they need them for the production process, which reduces inventory costs. This method requires producers to forecast demand accurately.

- Safety Stock Inventory: Safety stock is an additional quantity of an item held in the inventory to reduce the risk that the item will be out of stock. It acts as a buffer stock in case sales are greater than planned and/or the supplier is unable to deliver the additional units at the expected time.

- First In, First Out (FIFO): is an asset-management and valuation method in which assets produced or acquired first are sold, used, or disposed of first. For tax purposes, FIFO assumes that assets with the oldest costs are included in the income statement’s cost of goods sold (COGS).

- Last In, First Out (LIFO): Last in, first-out (LIFO) is a method used to account for inventory. Under LIFO, the costs of the most recent products purchased (or produced) are the first to be expensed. LIFO is used only in the United States and is governed by generally accepted accounting principles (GAAP).

- Reorder Point Formula: The reorder point is the level of inventory that triggers an action to replenish that particular inventory stock. It is a minimum amount of an item that a firm holds in stock, such that, when a stock falls to this amount, the item must be reordered.

4 Best Ways to Manage Inventory

When it comes to your inventory, you should always be trying to find the best ways to manage your inventory in order to reduce costs, increase profit, improve customer service, have the right amount of stock, reduce human errors, et cetera.

And while there is no one-fit blueprint that fixes all inventory challenges and transforms your organization into a perfect inventory management operation, but, there are certain ways to improve how you handle and manage your inventory, and here are the four best ways to manage your inventory:

- Implement Inventory Management System: Digitalization is an important part of improving business processes and that same applies to inventory management. The inventory management system can help you better manage your inventories, improve, and standardize processes, increase productivity, reduce errors, and there are many more benefits of having an inventory management system. That’s why it is one of the best ways to take to improve how you manage your inventory.

- Use Inventory Management Techniques: Inventory management techniques have been developed specifically to improve the management of inventory. That’s why using such techniques can improve the way how you operate within your warehouse, order inventories, manage inventory, and more. That’s why applying relevant techniques to your business can improve the way how you manage inventory.

- Follow Inventory Best Practices: Inventory Management best practices are another great way to improve how you manage your inventories. These best practices come from experience from other companies and professionals that faced problems like you and came up with a solution or ways to improve inventory management. That’s why you should constantly check for the latest inventory management best practices to implement for your company.

- Prioritize Your Customers: In the end, your inventory is meant to be sold to customers. That’s why one of the best ways to improve your inventory management is to listen to feedback from your customers. Often your customers can be the best source of information to even improve your internal processes, whether it is order fulfillment, quality of your products, or something else, your customers will let you know what you should improve, so listen to them!

Of course, there are other ways to improve your inventory. However, I would say these are the fundamental steps to undertake if you want to improve the way how you handle and manage your inventory.