(Source)

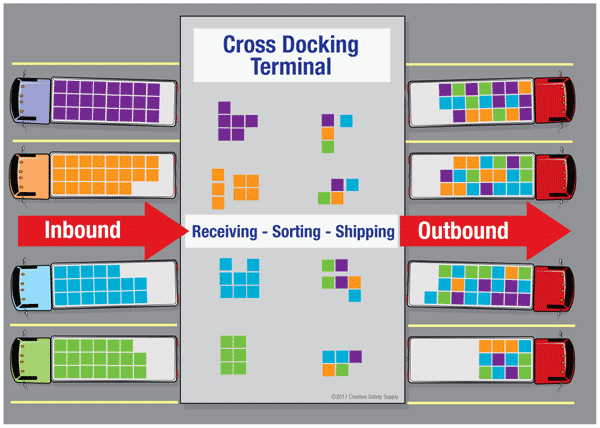

Cross-docking solutions allow companies to expedite shipments to customers, which means that customers often get what they want when they want it — the goal of an optimized supply chain.

Overall, there are several main benefits to incorporating cross-docking:

- Streamlines the supply chain, from point of origin to point of sale.

- Reduces labor costs through less inventory handling.

- Reduces inventory holding costs by reducing storage times and potentially eliminating the need to retain safety stock.

- Products reach the distributor, and consequently the customer, faster.

- Reduces or eliminates warehousing costs.

- May increase available retail sales space.

- Less risk of inventory handling.

- No need for large warehouse areas.

- Easier to screen product quality.

9. Cycle Counting:

Cycle counting means taking a small part of your inventory in the warehouse and counting it on regular basis with the goal of counting the entire inventory over a set period of time in order to ensure your physical inventory counts match your inventory records.

With cycle counting, companies are able to track their inventory records more accurately while reducing the amount of time of doing inventory audits. This will give you a better view of inventory in your storage and improve your purchase planning as you know whether you have enough or not enough stock for your operation.

Cycle counting has become a popular inventory management strategy for companies across all industries. Other benefits include:

- Improvement of the closing process.

- Higher order fulfillment rates.

- A more efficient operation overall.

- Possible elimination of annual counts

- Better customer service levels.

- Decreased audit fees.

- No employee overtime costs.

- More accurate inventory assessments.

- Higher sales.

- Fewer errors.

- More time between physical counts.

- Fewer inventory write-offs and obsolete inventory.

And cycle counting is an easy method that can be performed by anyone or any business. It’s an efficient and quick way to manage and optimize your inventory.

10. Bulk Shipments

Bulk Shipments is the transportation of goods in large quantities, usually not packed but loaded directly into a vessel. Such goods are grains, petroleum products, iron ore, and more. As such, these products are sent without any protective packaging or packing, and the object transporting them, usually the ship’s hold, acts as the container.

Bulk shipment allows companies to save on transportation costs by transporting a huge amount of inventory at once. Often this is suitable for the production of stable products such as grains for food, steel for different types of products, and other items that are distributed across many different manufacturing companies.

It is an essential logistic technique for our modern society to allow companies across the world to access materials and products from the worldwide market in order to create cheaper or higher quality products by sourcing the right materials.

11. Inventory Automation

Inventory automation means using an inventory management system that is capable of automating manual and repetitive tasks on its own with little human effort in order to increase business performance, reduce human errors and increase productivity.

An inventory automation system that automates tasks and creates workflows is used by retailers, manufacturers, wholesalers, distributors, and other businesses that manage inventory.

Using inventory automation is an essential step for every growing business. The more inventory the business handles, the more complex processes become, and the more workforce is required to manage the growing inventory.

So in order to cope with it, businesses introduce automation to solve some of the challenges with growing business and inventory management such as complex financials, keeping inventory records, managing purchase orders, and more.

Here are some of the biggest inventory automation benefits:

- Reduce human errors.

- Time savings.

- Real-time inventory visibility.

- Increase business and employee productivity.

- Further support business growth.

- Improve collaboration across departments.

With that, selecting the right inventory management software can be a challenging task and it depends on many different factors which one is the best for your case. For example, Dynamics 365 Business Central comes with advanced inventory and warehousing modules that are suitable for SMBs who are searching for a complete ERP system to centralize the entire operation.

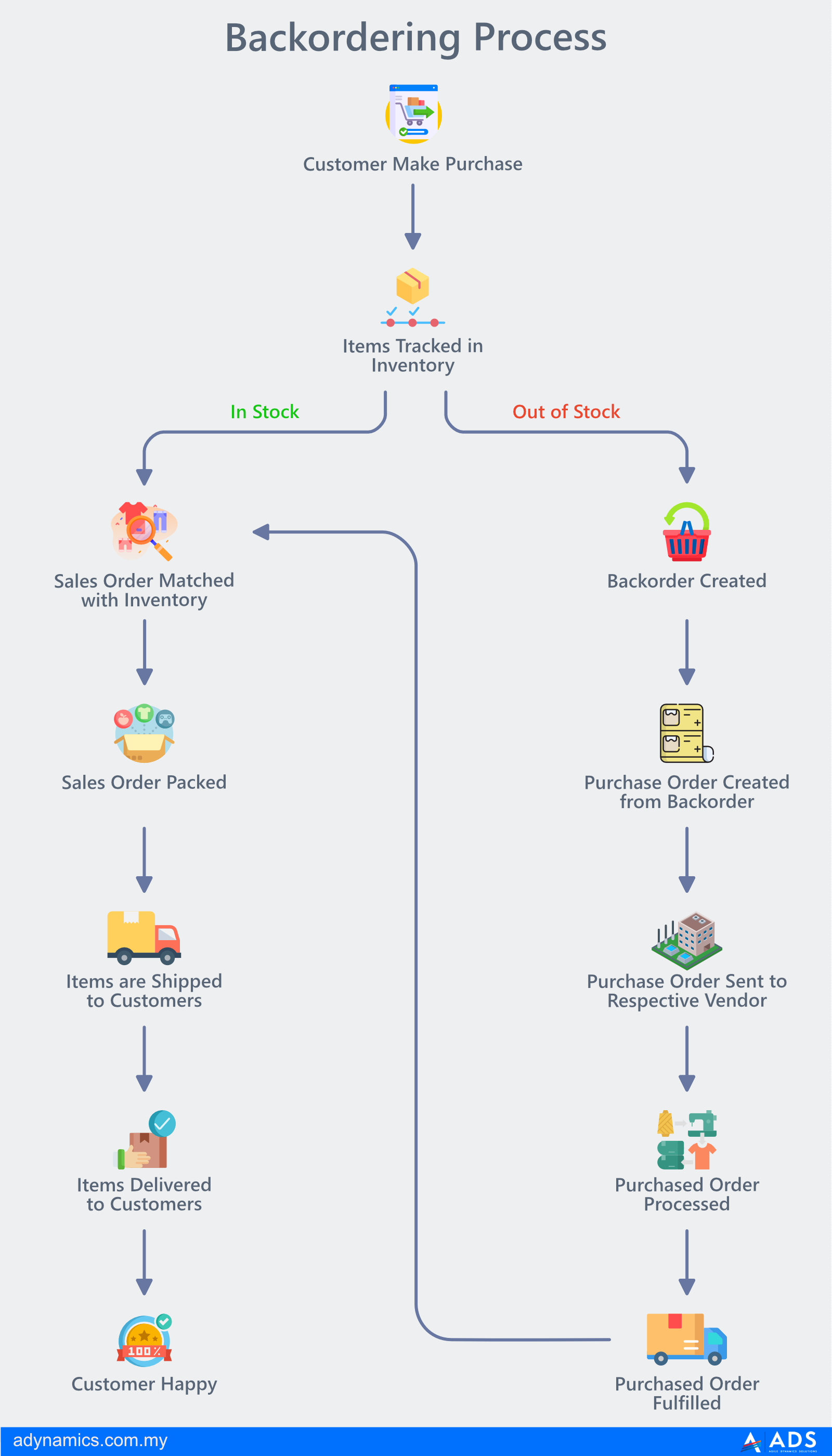

12. Backordering

Backordering is a process that allows businesses to take orders even if they don’t have sufficient stock in inventory. This process is very common among retailers or manufacturers to better manage orders.