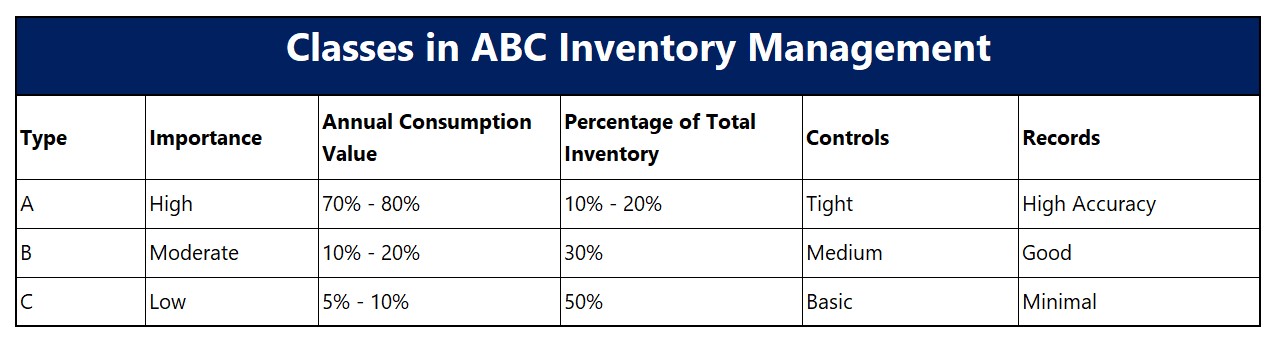

ABC inventory helps companies refine operation processes such as cycle counting, reorder points, and safety stocks. This ultimately lets businesses control working capital costs more easily, reduce obsolete inventory and improve the inventory turnover rate.

ABC analysis is an important method of inventory control it helps to keep costs under control while allowing companies to maximize profit opportunities.

By focusing on the highest value goods and not on many low-value goods allows you to leverage imbalances of sales and have the appropriate amount of stock based on the class assigned to a stock.

ABC analysis is being considered one of the main inventory analysis methods being used by companies from the very beginning.

However, only a few companies really practicing it as it requires actively collecting and analyzing data.

That’s why implementing ABC inventory analysis is considered one of the most important inventory management best practices that your business in Malaysia should implement.

7. Improve Your Inventory Forecasting

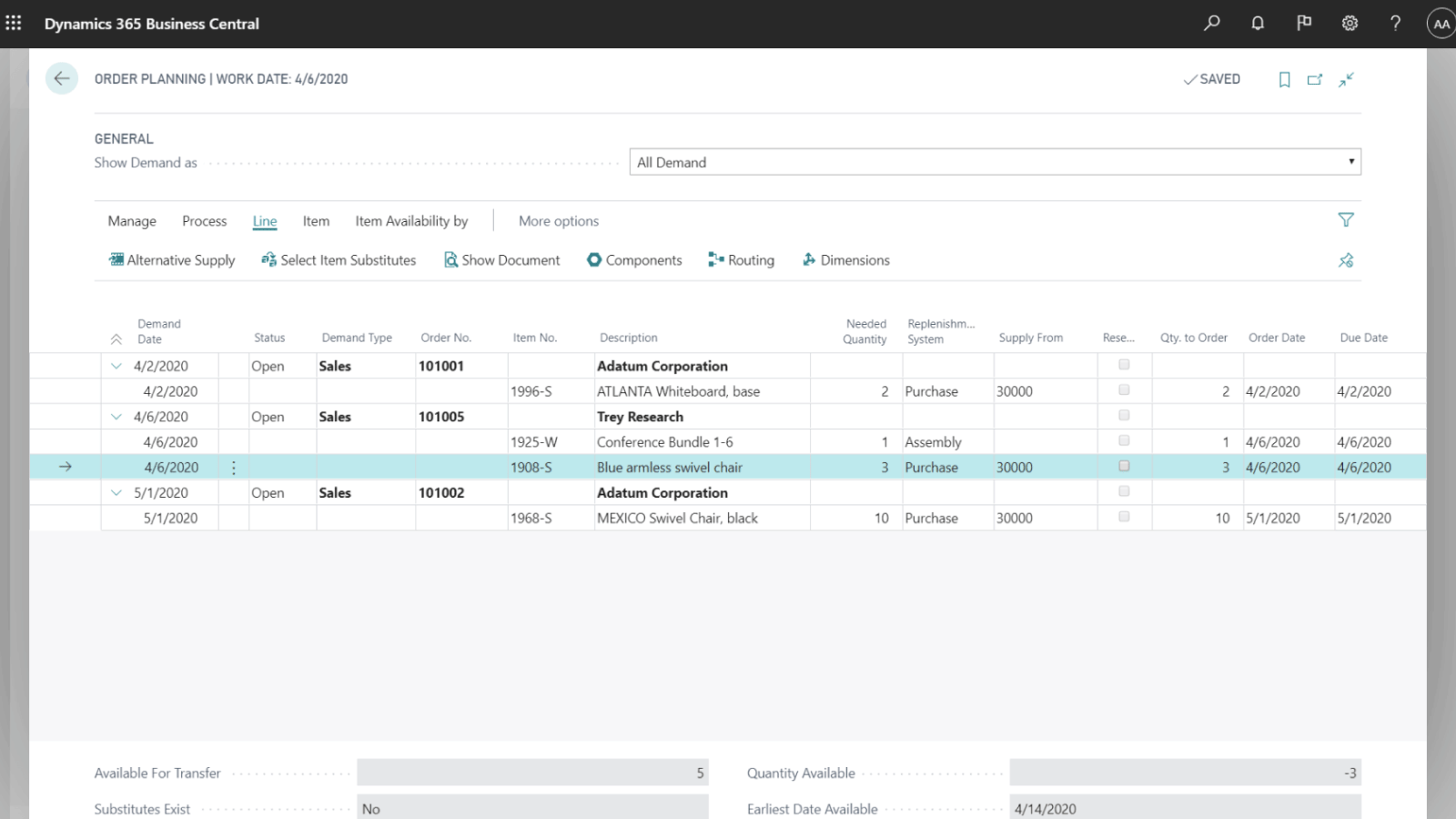

Are your decisions based on gut feelings or data? Being able to accurately predict customer demand to ensure stock availability and speed of delivery without overstocking are key factors for business in both B2B and B2C industries.

Inventory forecasting is the key to business high profitability, delivering excellent customer experience as well as minimizing the risk of having too much or too little stock.

Proper replenishment planning always starts with accurate demand forecasting and to do that, your business needs to have access to historical data for each item in your warehouse to understand their demand.

Inventory forecasting is an advanced inventory management practice as you’ll need to have implemented enterprise resource planning (ERP) or warehouse management system (WMS) that provides demand forecasting capabilities.

Depending on the system you are using or going to implement different forecasting and AI capabilities you will have access to.

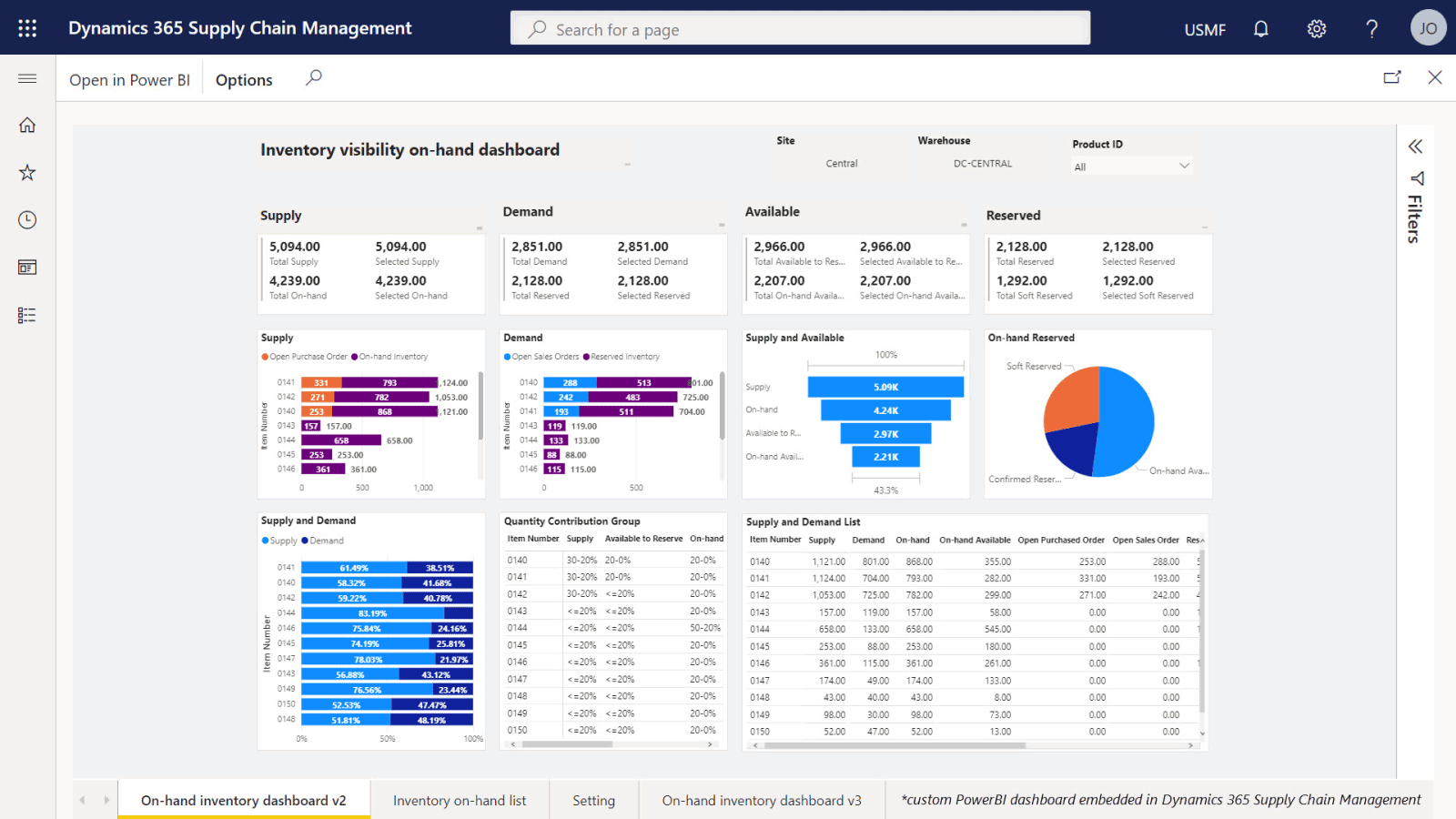

For example, Dynamics 365 Supply Chain Management offers to:

- Generate a statistical baseline forecast that is based on historical data.

- Use a dynamic set of forecast dimensions.

- Visualize demand trends, confidence intervals, and adjustments to the forecast.

- Authorize the adjusted forecast to be used in planning processes.

- Remove outliers.

- Create measurements of forecast accuracy.

Or with Dynamics 365 Business Central demand forecasting is used to predict independent demand from sales orders and dependent demand at any decoupling point for customer orders.

8. Reduce Your Inventory

Most inventory-based businesses, spend more money on their inventory than on real estate, labor, and merchandising – making it their largest investment.

Inventory accuracy hovers around 63% studies show which means inventory levels are chronically inaccurate meaning that there is a big chance of overstocking and a large part of your working capital being tied up into inventory that could be used to grow your business better somewhere else.

Therefore, inventory reduction methods should always be regarded as inventory management best practices and incorporated into the company culture in order to optimize inventory performance.

9. Implement Automation

Inventory automation is arguably one of the best ways to improve workforce efficiency, reduce human errors, do more with less, and definitely improve the well-being of your employees.

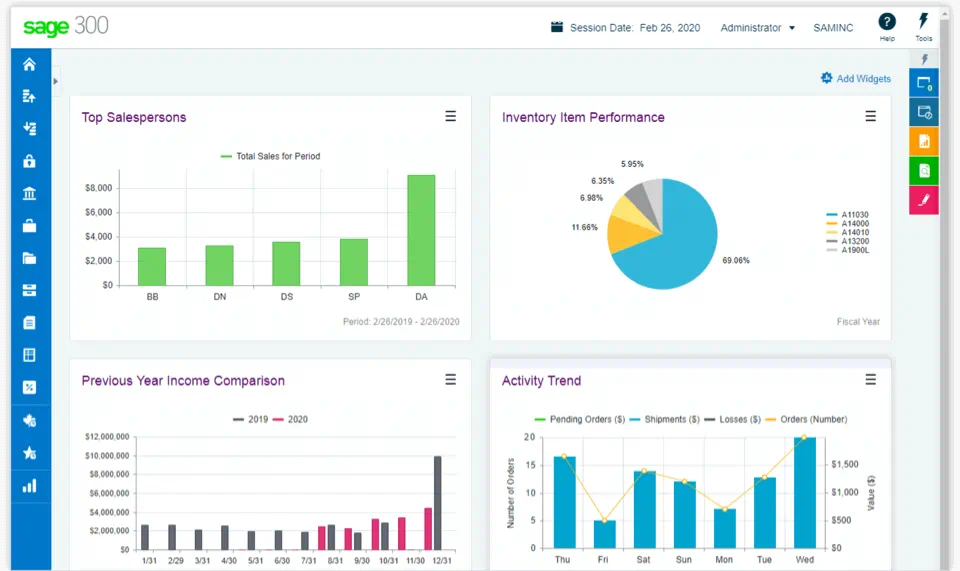

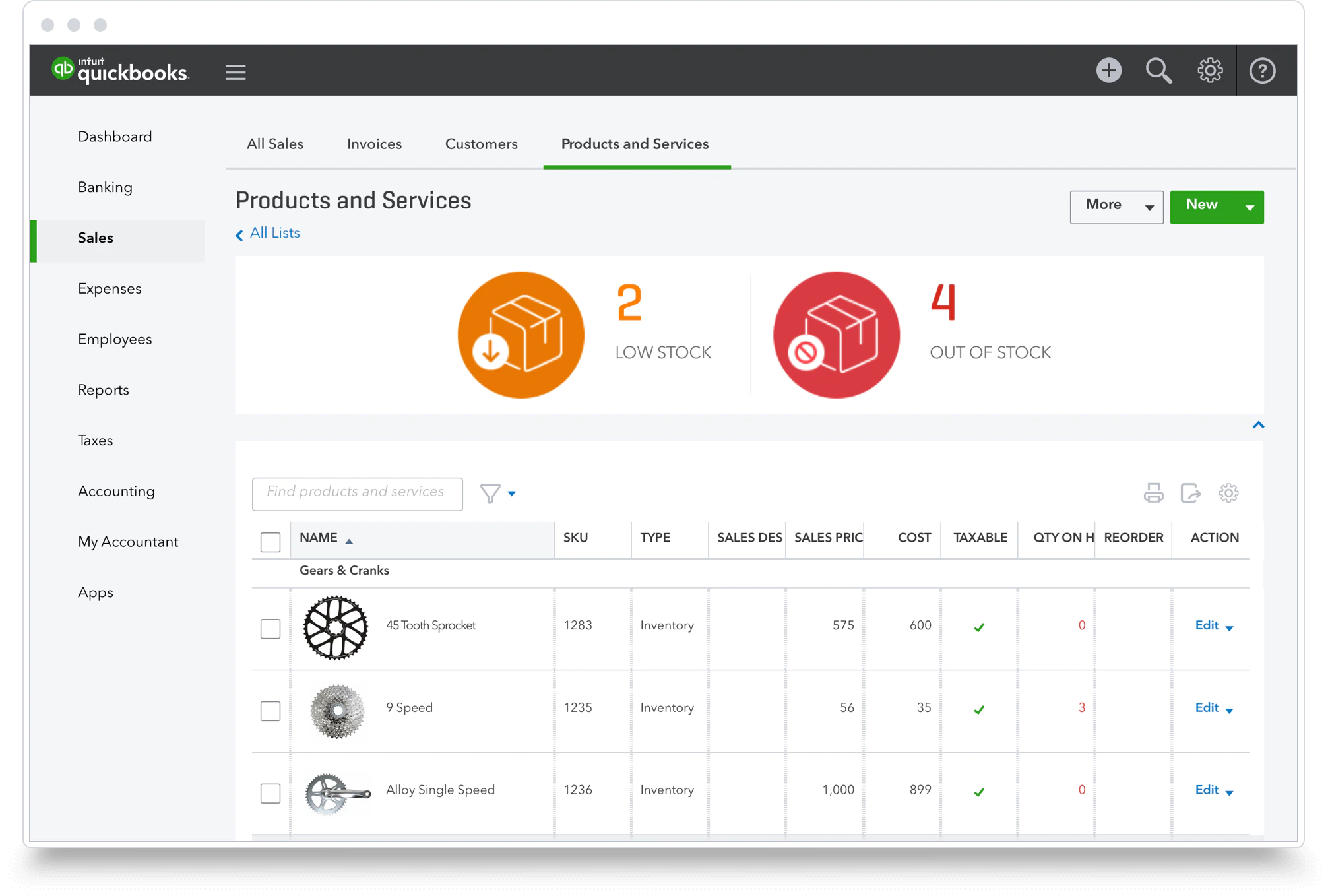

By implementing inventory or warehouse management solutions you will be able to access powerful automation capabilities to help you optimize your entire inventory and distribution process. You can automate everything from drop shipping to backorders, partial fulfillment, order invoicing, customer tagging, inventory counts, forecasting, Bills of Materials (BOM), and more.

Complete inventory management systems give you the power to handle your stock across the entire business, from barcode scanning to order fulfillment to sales reporting.

And with a robust ERP system with inventory and warehouse capabilities, you can take it to step further by automating processes across sales, service, finance, and operation enabling you to boost your business productivity to the next level while reducing human errors to a minimum.

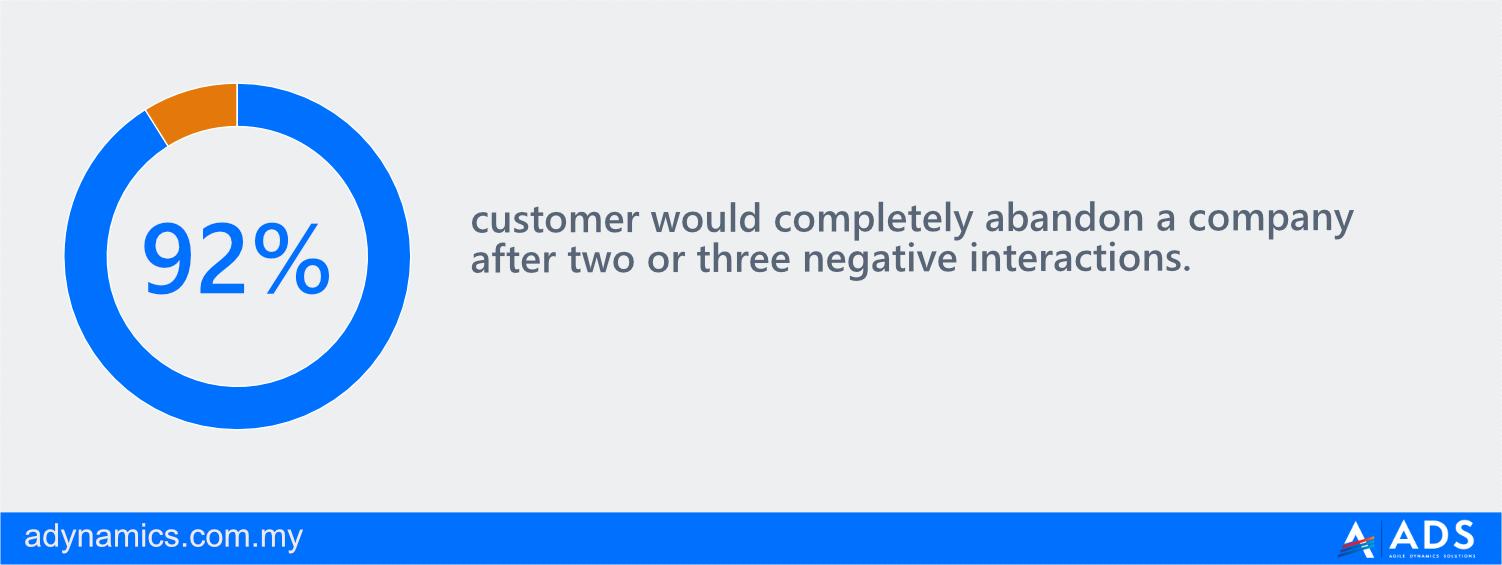

10. Implement Strict Quality Control

With digital channels bringing more and more sales revenue to the business, it’s even more important to implement strict quality control. Unlike in the usual brick-and-mortar shop where people can inspect your items by themselves, in online channels, customers rely on your ability to deliver exactly what they order without any damage, fault, or imperfection.

Not implementing strict quality control, especially for your products being sold online can cost you more than just returned packages and refunds, but your reputation as well.

In fact, 1 in 3 customers will leave a brand they love after just one bad experience. (PWC)