Inventory control helps you to maximize your profit while the least amount of inventory possible is located in your warehouse/s without compromising on customer satisfaction or operational efficiency.

Inventory control helps you to improve the accuracy of inventory levels. In fact, for retail, inventory is accurate just 63% of the time, on average.

And according to the US Census Bureau, manufacturers and retailers were holding $1.33 of inventory for every $1 in sales and a similar ratio can be expected in other countries in SEA like Malaysia, Singapore, or Cambodia.

Effective Inventory control allows you to change that inventory/sales ratio for the better. Stationary stock does not do anything for your business or its bottom line. Make the most out of the precious space you have, while ensuring you always meet customer demand.

Inventory Control Benefits:

Here are some of the inventory control benefits:

- Improved Quality Control: With better inventory control also comes improved quality control of your products ensuring your customers get the best products. It also helps you to accurately rotate your products from your warehouses in order to minimize the time you hold to the inventory. Inventory control helps you to also track your vendor performance for the quality they deliver, reliability of their supply chain and what vendors’ products are being returned, and how often.

- Improved Accounting Accuracy: Another benefit of inventory control is improved accounting accuracy of the inventory asset you have and writing off obsolete and spoilage items which improve your inventory and tax audit by keeping better track of your inventories.

- Have Real-Time Inventory Levels: Having a clear idea of where and how many inventories you have currently in your warehouse/s allows you to optimize your operations and reduce any last-minute orders or overtime for employees which can save you a lot of money and hassle. It also helps you minimize any double reorders of the same items.

- Better Organizational Control: Essentially inventory control means organization control as inventory is often the largest asset companies have. Well organized warehouse gives you a better view of your inventories and increases employee performance and efficiency. It gives you better control of your business and allows you to more focus on your customers than managing your inventory.

- Improved Inventory Cost: With a better view of your inventory levels, the quality of inventory delivered by vendors, and the popularity of your products, you can effectively manage your inventory cost in order to spend the least amount of money on inventory while maximizing your profit.

- Better Long-term & Short-term Forecasting and Procurement: With a better view of your inventory, quality control per vendor, historical data performance, and more you will be equipped with important data to make better decisions and improve your purchasing processes and vendor relationships.

- Improves Internal Stock Handling Efficiency: Inventory control is a part of inventory optimization, you can improve the handling, recording, and tracking of your inventory and correct any inventory inaccuracies. This will boost business efficiency with better and more optimized labor performance.

- Optimize Your Logistic Workflow: With better inventory control you will have a better view of what’s needed, what is coming, and what will be needed, improving your logistic flow ensuring you minimize any delays or shortages in your inventory and keep customer satisfaction high.

- Generate Real-Time Reports: The inventory control system allows you to create reports in real-time to make timely and smart decisions that propel your business growth. This will help you with your current and future planning, analyze trends and make decisions faster.

- Financial Savings: One of the biggest inventory control benefits is the financial savings you can achieve with it. By improving and streamlining your stock ordering, inventory management, and keeping the least amount of inventory to effectively run your operation without any customer experience sacrifices, you’ll maximize your financial savings and your profit as well.

- Reduce Human Errors & Inaccuracies: Inventory control together with a system can reduce the number of manual processes required by employees to perform and you can create automation and workflows for labor-intensive, errors prone processes and data recording and tracking processes to minimize any human errors.

What is Inventory Control System?

An Inventory control system is software that helps you to monitor inventory movement, usage, and storage and automatically updates your inventory levels. It can use historical data to improve forecasting and allow you to set inventory policies and automatically reorder points.

This technology will integrate and manage purchasing, shipping, receiving, warehousing, and returns into a single system to improve company inventory handling, supply chain, and customer satisfaction.

An inventory control system can include numerous features to improve workflow, inventory tracking, and management of your inventory such as:

- Barcode scanner integration

- Complete inventory counts

- Keeping track of physical inventory with sales and purchase orders

- Product details, locations, and histories

- Reports and adjustments

- Inventory tracking

- Inventory report

- Inventory forecast

- Inventory alerts

An inventory control system helps you to cut down on holding costs as reducing stock-outs and overstocks can lower your overall inventory costs by 10%. Having good inventory control features is the key point for a smooth inventory process.

When investing in an inventory control system, you should prioritize technology that can integrate with other business processes such as POS systems to track sales and stock levels in real-time across multiple channels of your business.

Types of Inventory Control System

As technology is evolving, inventory control systems went through changes over time as well from simply tracking the number of SKUs and their amount all the way to making intelligent automation, workflows, reports, and forecast for business owners and inventory managers to make better and faster decisions and increase productivity.

And there are two key types of inventory control systems that you should know:

- Perpetual Inventory System: This is a program that continuously estimates your inventory based on your electronic records, not a physical inventory. This system starts with the baseline from a physical count and updates based on purchases made in and shipments made out.

- Periodic Inventory System: Only updates the ending inventory balance in the general ledger when a physical inventory count is conducted. Since physical inventory counts are time-consuming, few companies do them more than once a quarter or year.

Best Inventory Control Systems

The best inventory control system will automate a lot of manual processes. It will provide an accurate picture of what inventory you have, where it is, and when you need to reorder to keep your stock at optimal levels.

- Dynamics 365 Business Central (Best Overall for SMB): Dynamics 365 Business Central is an all-in-one ERP business management software, that centralizes your entire operation from finance, sales, warehouse & inventory to operations. This is the best option for Malaysian businesses who wants a complete ERP system with advanced inventory and warehouse functions. Check out our guide on ERP inventory management.

- Lightspeed Retail (Best for Restaurants):

- Zoho Inventory (Best Free Option): Zoho Inventory is an online inventory management software with a robust free version and affordable paid plans. For small businesses or start-ups, Zoho Inventory lets you add items, fulfill orders and view inventory from any device, making it the best free option.

- UpServe (Best for Retail): This combination point of sale (POS) and inventory management program is built for small retail shops with stock tracking tools, tons of integrations, and excellent e-commerce capabilities.

- QuickBooks Inventory (Best for Small Business): QuickBooks is the ideal solution for Malaysian small businesses with great inventory control capabilities and it can be easily integrated with their accounting software for streamlined operation.

- Dynamics 365 Supply Chain Management (Best for Enterprises & Manufacturing): For medium to large size enterprises, Microsoft has developed advanced supply chain management software with the latest and advanced warehouse and inventory features and technologies. This solution is ideal for medium to large enterprises and manufacturing companies in Malaysia.

Inventory Control Best Practices & Tips

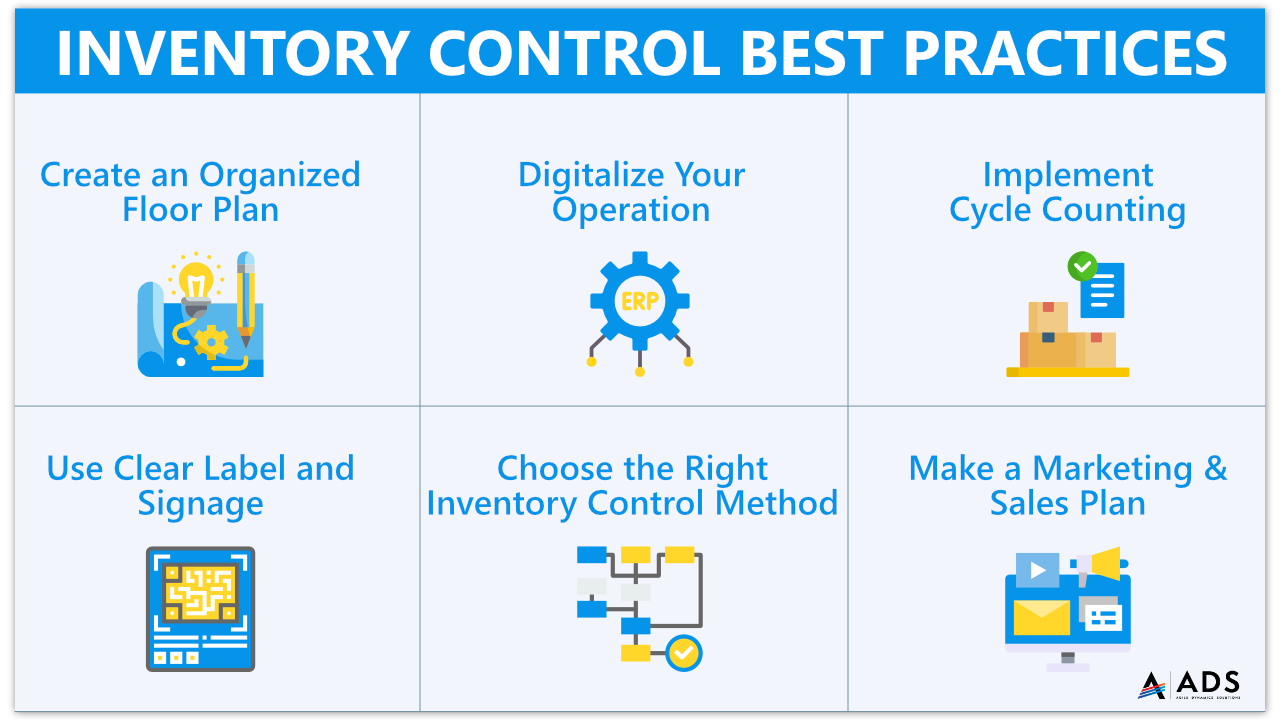

As you could see, inventory control is an essential part of inventory management. Following are some of the inventory control best practices and tips:

- Create an Organized Floor Plan: Having an organized warehouse is the first step toward proper inventory control. Having bestselling items closer to the shipping area, products organized by categories, and a floor plan that makes sense will increase your employee productivity minimize wasted time and it will improve their wellbeing.

- Digitalize Your Operation: Digitalization is part of every industry, and it can greatly improve business outcomes by automating repetitive tasks, creating powerful workflows, streamlining operations and so much more. Using an ERP system, WMS, or inventory management system will greatly improve your operational efficiency, save costs and generate more profit.

- Implement Cycle Counting: Cycle counting is the act of counting items in small sections over certain cycles. Rather than counting everything at once, which may be very time-consuming, cycle counting enables you to maintain effective inventory control and determine inaccuracies quickly.

- Use Clear Labels and Signage: Proper labels and signage being implemented within your warehouse will improve your fulfillment process. By ensuring you have clear and concise labels on all aisles, racks, bins, and products will greatly improve your warehouse and supply chain processes and even reduce human errors or injuries.

- Choose the Right Inventory Control Method: There is no one-size-fits inventory method that will perfectly work for every warehouse. Therefore, it is important to ensure you implement the right inventory control method that works the best for your business and industry.

- Make a Marketing & Sales Plan: Having a clear plan of what will be promoted, what products need to go to remove inventory before they become obsolete, and what sales will try to sell the most will help you prepare your warehouse operation for any rush, organize products for faster fulfillment time and ensure you have enough products to avoid any stockouts. Having clear marketing and sales plan will increase your profit and warehouse productivity.